Shrink Wrapping

Bradman Lake’s experience with shrink wrapping is second to none. Our machines are suitable for all industries that require shrink wrapping for presentation, protection and transit purposes.

We offer twin-reel machines where the film is heat-sealed and single-reel machines where an overlap seal is employed. The range includes low cost pneumatic machines and high-speed full servo machines, both equipped with low energy consumption

shrink tunnels.

Packaging Styles

Models

The SRW High Speed Shrink Wrapper machine is designed to wrap a collation of products at speeds up to 50 packs per minute. These machines use a different film application method to a conventional shrink wrapper and operate without any form of sealing jaw.

The film is taken from a single reel cut to length and then applied around the product with an overlap underneath the pack. This overlap is sealed as the pack passes through a heat tunnel. Apart from the higher speeds obtainable, the absence of a sealing jaw leads to lower maintenance. Also, the film which is pre-cut to length facilitates the use of printed and registered film. This type of machine is normally supplied with appropriate collating equipment and often works in conjunction with tray packing equipment. Certain products can be wrapped unsupported. Although suitable for a wide range of applications, the equipment is most likely to be used for the wrapping of cans, jars & bottles.

The RTSW Right-angle Shrink Wrapper is a side fed, fully automatic, tight sleeve wrapper with an angled sealing/cutting jaw which reduces film and energy usage compared to standard shrink systems. The wrapper has an integral shrink tunnel and typically operates at up to 35 packs per minute and faster using a twin lane machine. The machine comes in two variants, the RTSW (pneumatic) and RTSWS (servo) and three sealing jaw widths as standard. Although the RTSW can be supplied as a ‘stand alone’ machine it is ideally suited as part of an integrated system and complements other machines within the Bradman Lake Group.

This machine can also be adapted to include an integral tray wraparound facility where the product is collated onto the tray blank and a female tray former is lifted in order to wrap the tray sides around the product after having hot melt glue applied. This application is particularly useful when factory space is at a premium and a shelf ready option is required.

The ITSW Inline Shrink Wrapper is an inline fed, fully automatic, tight sleeve wrapper with an angled sealing/cutting jaw which reduces film and energy usage compared to standard shrink systems. The wrapper has an integral shrink tunnel and typically operates at up to 35 packs per minute and faster using a twin lane machine.

The machine comes in two variants which are the ITSW and ITSWS, which is a servo controlled version of the standard ITSW, which allows the machine to operate at a faster speed via precisely controlled motors on the sealing jaw and either a flight bar infeed assembly or belt to belt infeed conveyors. Although the ITSW can be supplied as a ‘stand alone’ machine it is ideally suited as part of an integrated system and compliments other machines within the Bradman Lake Group.

A Highly Flexible Shrink Wrapper for Beatson Clark

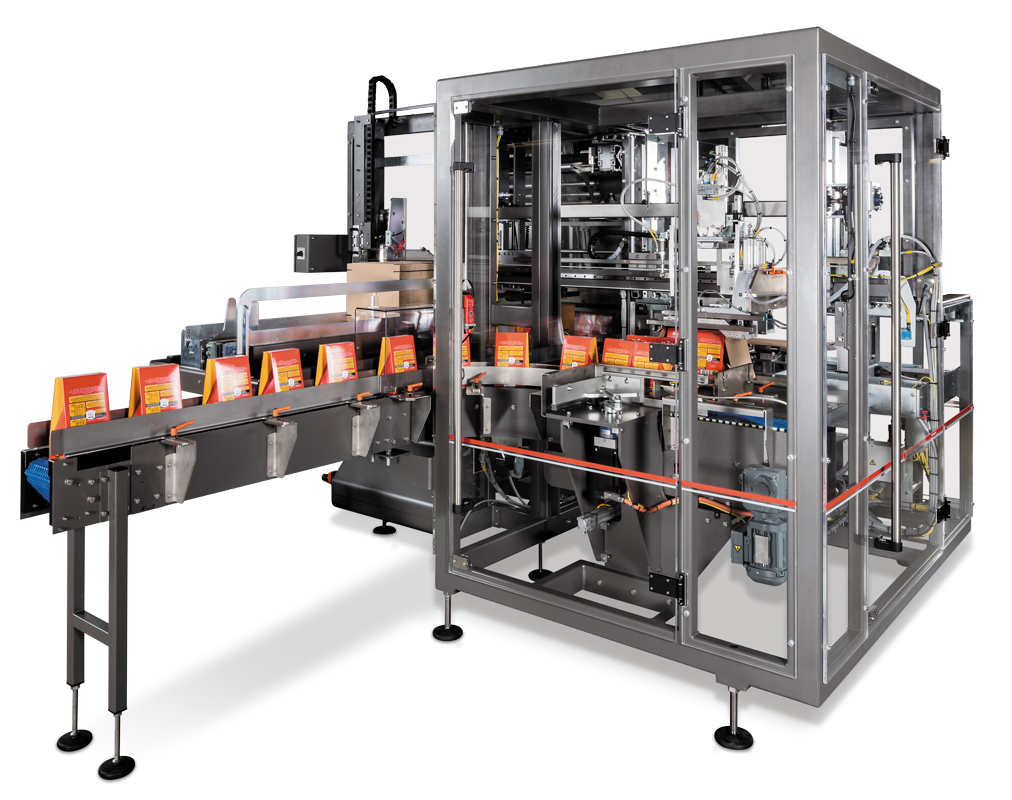

Beatson Clark (BC), wanted to upgrade one of their production lines, by installing a new bottle packaging system to handle a wide range of bottle sizes and shapes. Bradman Lake (BL) the UK’s largest manufacturer of packaging machines delivered a new flexible high-speed machine with integrated collator, robot loader and energy efficient shrink wrapper.

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request