Register for free using code 49U44

Bradman Lake is excited to unveil its latest innovations at Pack Expo International 2024, held at McCormick Place in Chicago from November 3rd-6th. Attendees are invited to visit booth S-2058 to explore the diverse range of state-of-the-art packaging technologies, tailored to meet the dynamic needs of today’s manufacturing environments.

All Bradman Lake machinery is delivered and supported by award-winning customer service. It has been specifically designed to meet today’s packaging challenges, improving flexibility and efficiency to increase profitability.

In addition to our industry-leading build times, all showcased equipment will be available for immediate sale.

Innovation Spotlight: Multi-functional Vision Guided Robotic Loader

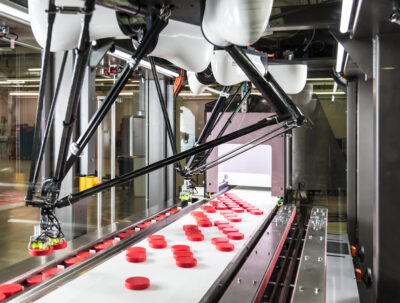

The highlight of this year’s exhibit is Bradman Lake’s multi-functional VGR Vision Guided Robotic loading system. The VGR is showcased as part of a fully integrated flexible packaging line, emphasizing exceptional versatility by seamlessly loading products into both cartons or the infeed of a multi-pack flow wrapper.

This advanced system will be supplied with top load cartons (cartons supplied by Oliver Inc) formed on the HS Mini Single Head Former, with loaded cartons subsequently closed using the RA60 Right-Angle Carton Closer. Additionally, the VGR will demonstrate its multifunctionality by feeding products directly onto the infeed of the FT120 Flow Wrapper, giving our customers unprecedented flexibility to achieve two packaging formats on one system.

VGR Vision Guided Robot loading the infeed of a Flow Wrapper

VGR Vision Guided Robot loading top load cartons

Compact Design HS Mini Carton and Tray Former / Erector

Ideal for space constrained areas, the HS Mini Single Head Carton and Tray Former offers a compact footprint without compromising on advanced functionality. Despite its smaller size, the HS Mini retains all the features of its larger counterparts, providing the ultimate flexibility to handle a variety of carton formats and sizes. This machine is designed to meet fast-changing production requirements, offering quick changeovers and the ability to erect different styles of lock and glue cartons or trays.

HS Mini Carton Former / Carton Erector

Efficiency and Flexibility with the RA60 Carton Closer / Sealer

The RA60 Right-Angle Carton Closer, another featured machine, showcases Bradman Lake’s unique ‘Flexible Carton Control’ (FCC) technology. This innovative feature utilizes flexible rubber fingers to close cartons containing products of inconsistent size or protruding above the carton base walls, allowing cartons to be closed without jamming, ensuring smooth operation and reducing downtime. With its tool-less size changeover capability, the RA60 is perfect for customers running multiple carton sizes, maximizing productivity and minimizing interruptions to production.

RA60 right angle carton closer and sealer

High efficiency sealing with the FT120 Flow Wrapper

The FT120 Flow Wrapper sets a new standard for efficiency and seal integrity with options to accommodate the most challenging heat-seal applications. This innovative machine features improved, backward-compatible flow wrap sealing technologies, allowing for simple conversion parts or modular replacements to handle recyclable, biodegradable, paper, and single-substrate mono materials.

Equipped with a robust end crimp sealing module, the FT120 offers both hot and cold seal options to meet diverse packaging requirements. Bradman Lake’s unique Soft Jaw Technology prevents jams from misplaced products, enhancing reliability. The FT120 also boasts automatic reel-to-reel splicing, automatic web tracking, and intelligent features like “No Gap No Crimp” and “No Product No Bag” that increase productivity by reducing waste and preventing production stops. With high-speed capabilities of up to 1200 packs per minute, the FT120 Flow Wrapper is designed for peak performance in modern packaging operations.

FT120 Flow Wrapper

Showcasing the SL903 High-Speed End Load Cartoner with Cascade Loader

Bradman Lake will also display the SL903 High-Speed End Load Cartoner, renowned for its robust stainless-steel construction and ability to erect, load, and close cartons within a single frame. Equipped with a multitude of optional features, the SL903 can be customized to meet the specific needs of each customer. This machine will be fed by Bradman Lake’s innovative Cascade Loader, a system that utilizes servo-driven rotors designed to efficiently collate, synchronize, and load bagged products into the infeed pockets of the SL903 End Load Cartoner.

SL903 End Load Cartoner

A Glimpse into Bradman Lake’s Integrated Solutions

During the exhibition, attendees can view curated videos showcasing how Bradman Lake’s equipment seamlessly integrates across different packaging processes. These primary, secondary and tertiary processes include product distribution and flow wrapping, roll wrapping, cartoning (Carton Erectors, Carton Sealers, Side Load Cartoners), robotics, case packing, shrink wrapping, and palletizing. This showcase reaffirms Bradman Lake’s position as a leading one-stop shop for end-to-end packaging solutions: From Process to Pallet.

From Process to Pallet

Bradman Lake provides true, single-source turnkey systems, with project management from initial concept to site acceptance and beyond. The benefits to customers include: commonality of engineering standards and parts; common control standards and HMI look-and-feel; a single point of contact for procurement, project management and aftermarket services; FATs for complete systems occur in a single location and systems that are fully integrated and tested prior to shipment, resulting in a cost-effective and an expedited start-up.

Intuitive HMIs and a common control platform offer customers an easy method to monitor equipment from a single location, as well as seamlessly exchange upstream and downstream data.

Bradman Lake’s modular approach and innovative capabilities empower customers to stay at the forefront of packaging technology and automation. This approach ensures that customers can seamlessly upgrade to the latest advancements while maximizing their initial capital investment.

Tailored for Diverse Market Sectors

Bradman Lake’s innovative packaging machinery is designed to cater to diverse market sectors, including bakery & biscuit, chocolate & confectionery, dry foods, chilled & frozen foods, pharmaceutical, and consumer & healthcare. Each machine is built to deliver outstanding performance and reliability, making them ideal for unique manufacturing needs.

Visit Us at Pack Expo International 2024

Join Bradman Lake at booth S-2058 during Pack Expo International 2024 from November 3rd-6th and experience firsthand how our cutting-edge packaging solutions can enhance your operations. Discover the power of innovation and see why Bradman Lake is a leader in the packaging industry.

About Bradman Lake

Established in 1948, Bradman Lake provides innovative packaging solutions to an international client base. The company is a leading designer and manufacturer of packing machinery and turnkey systems to the bakery & biscuit, chocolate & confectionery, dry foods, chilled and frozen foods, consumer, pharmaceutical and healthcare sectors. In 2022 the company was awarded the prestigious Queens Award for Enterprise. Bradman Lake’s manufacturing plants are located at Beccles and Bristol in the UK and Rock Hill, SC, in the United States. Bradman Lake is a wholly owned subsidiary of the multi-disciplined UK engineering and manufacturing group, Langley Holdings plc.