End Load Cartoning

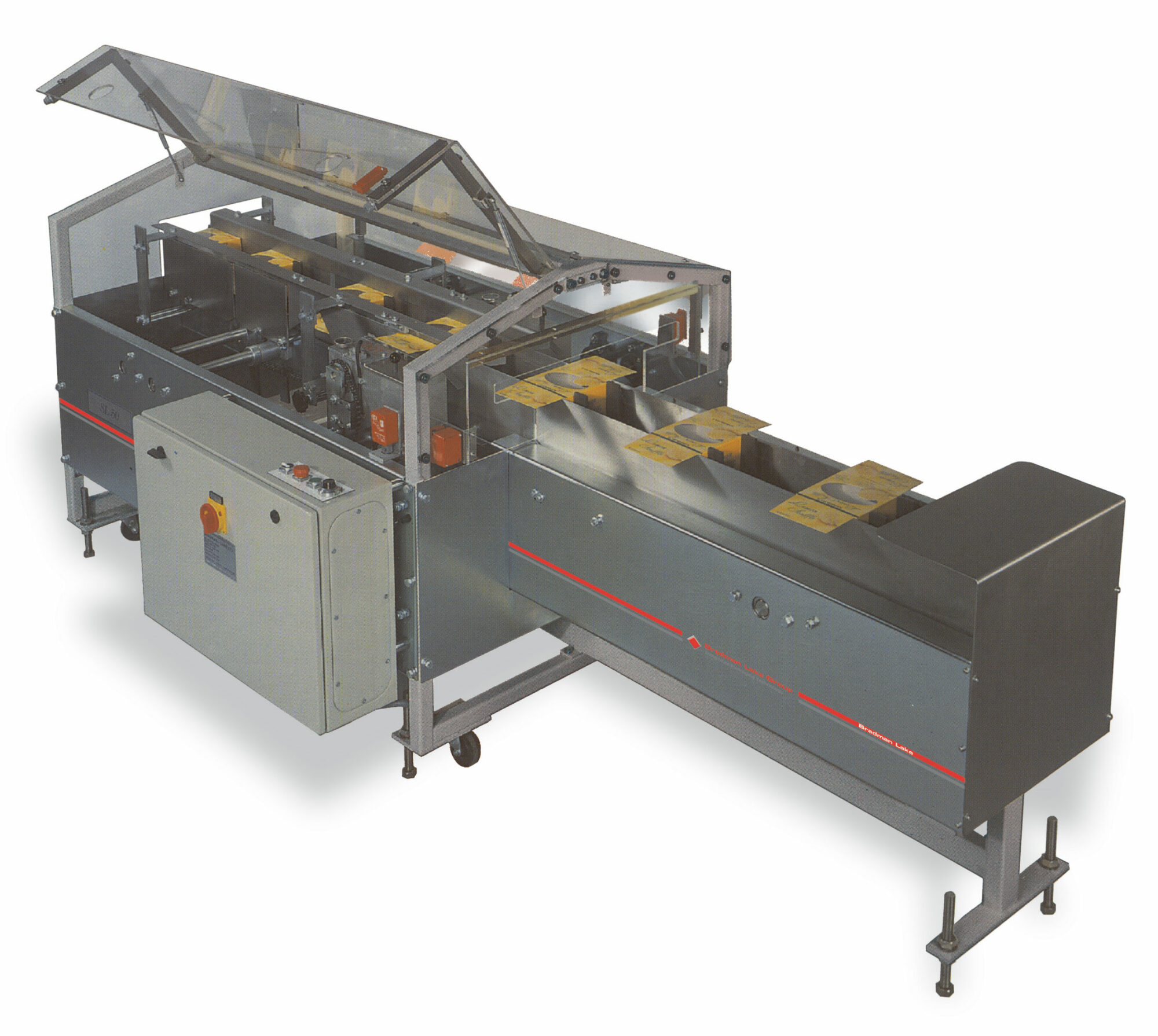

From entry-level hand-fed to fully automatic, Bradman Lake end load cartoning machines are renowned worldwide for their simplicity and adaptability and can load almost all products, from small delicate objects to large cereal bags.

They are also capable of handling a wide range of carton board at high speeds, with maximum efficiency.

A wide range of optional features, including low-level carton hopper, is available to enable the machine to be adapted to meet the customer’s specific requirements.

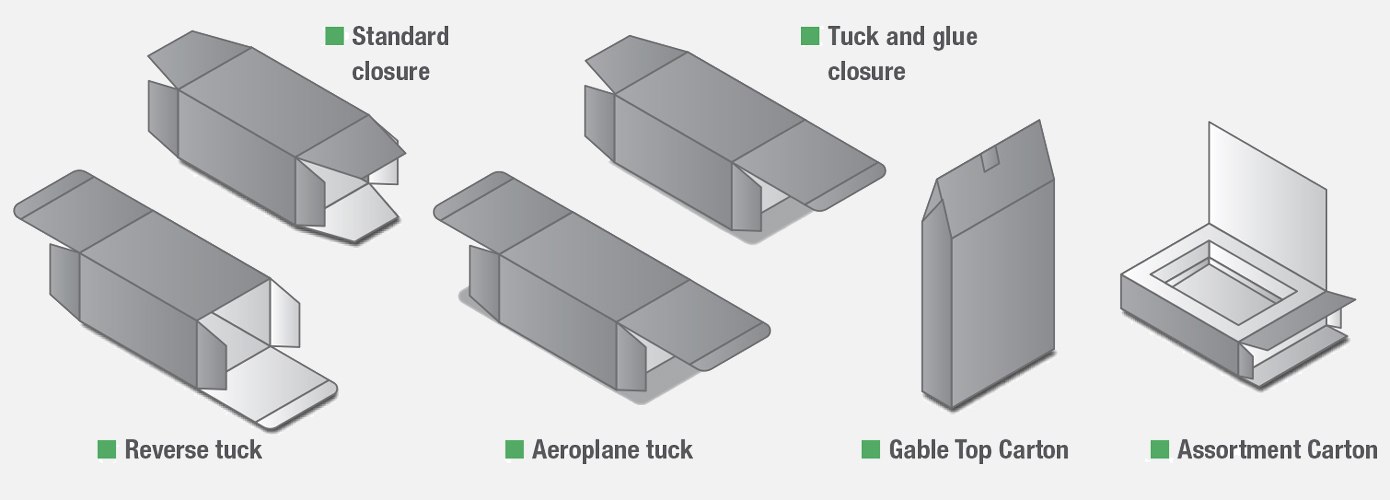

Packaging Styles

Models

The SL50 hand-fed End Flap Sealer is an entry-level machine that is regularly chosen by customers that value its versatility, robustness, mechanical simplicity, and reliability. Tool-less size change includes handwheel adjustment.

The SL80 and SL802 Semi-automatic End Load Cartoners can handle lower grade carton materials and are regularly chosen by customers that value its robustness, mechanical simplicity, and reliability.

The machines employ proven features, including powered carton feeders, fixed carton magazines, and hand-wheel adjustable carton transit conveyors. The SL80XL offers the same features combined with the capability of handling larger cartons.

The SL902 and SL903 Fully-automatic End Load Cartoners can handle a wide range of products and cartons, including lower grade carton materials, and are available with a variety of product infeed and collating systems for total automation with upstream equipment.

The simple yet strong stainless steel construction makes the machines ideally suited to the food industry and other market sectors.

Machine guarding has been designed to provide both maximum visibility of operation and excellent machine access.

The carton hoppers are motorised and include ‘slide in’ change part gates for quick and repeatable size changes. A low-level carton hopper option is available.

The SL904 and SL906 are fully servo-driven, automatic continuous motion End Load Cartoners. They are designed for large scale, high-speed cartoning operations. The servo motors power the rotary carton feeder, flap tuckers and flight chains as well as the product infeeds and transfer conveyors. Elimination of mechanical power transmissions ensures the SL904 and SL906 End Load Cartoners perform to a consistently high level of efficiency with very low maintenance costs.

The machines employ a heavy-duty, smooth running barrel cam product loader that incorporates overload detection in the event of product jamming. The barrel cam loader pusher arms are easily retracted for product removal. Standard features include automatic lubrication, servo-assisted, and tool-less size changing.

The SL Minor is a smaller footprint high-speed end load cartoner with integrated servo driven star wheel feeder. It is suitable for customers with limited floor space.

The IMSL Intelligent Motion Side Loader is the latest model of end load cartoners. The IMSL Incorporates iTRAK® technology, which has been utilised for flexible product collating while reducing the number of transfers using guided pockets to ensure minimal product handling and repeatable carton loading. A new servo-driven linear inserter tracks the guided pockets and transfers each product into the carton, negating the need for a traditional ‘barrel loader’. This delivers excellent access for the end-user, with the option of constant or indexing motion on the same machine and greater flexibility in handling a wide range of products and collations with minimal rapid size changes.

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request