Case Packing

Bradman Lake offers both pre-formed case and wraparound case packers in combination with appropriate collators for an extensive range of products. Where a pre-formed case is used, there are three machine type options; side load, bottom load, and top load depending upon the nature of the product, its handling ability, and the required format within the case.

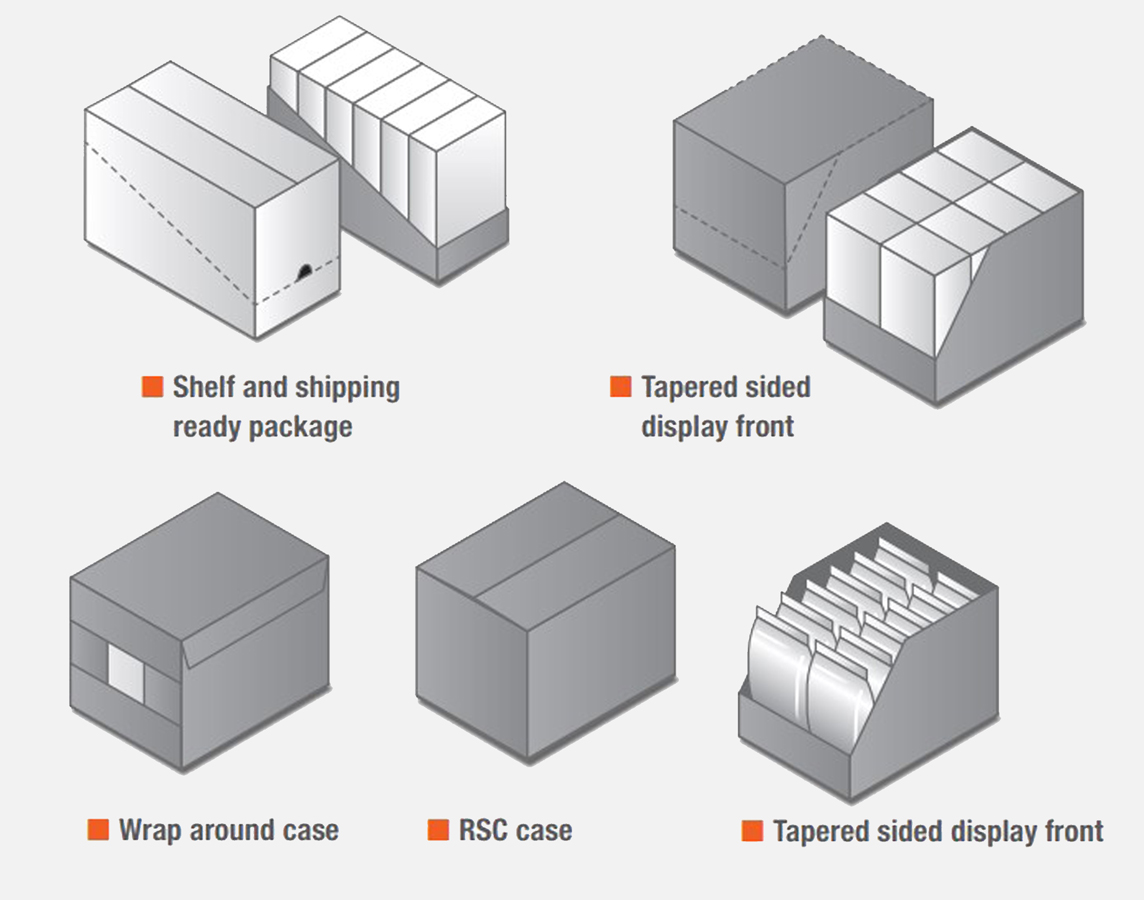

Packaging Styles

Our versatile lineup of case packers designed to meet the dynamic requirements of contemporary shelf-ready retail environments. Each machine in our range is proficient in handling both corrugated and carton board materials. Our case packers offer the flexibility of sealing RSC cases with either adhesive tape or hot melt adhesive, providing a comprehensive and adaptable solution to cater to diverse packaging needs.

Models

Side Load (SLCP) and Bottom Load (BLCP) Case Packers pre-collate products into the required formats before loading them into standard RSC cases. Selection of the style of machine is dependent upon the type of product, for example bottom loading is used for bottles or applications where a product must remain upright. Side loading is particularly suitable for cartons, especially where the top end of the cartons must be visible upon opening the case flaps.

The MX Robotic Top Load Case Packer is extremely flexible due to its modular design. Combinations of modules can be constructed to suit all applications, including other non-cartoned products. The module principle ‘future proofs’ the machine allowing for variations and upgrades to be implemented easily when production and marketing demands change.

The MX Robotic Top Load Case Packer can be supplied with a flat belt or dual race track (DRT) infeeds to suit various product types and collation formats. For ultimate flexibility, the machines can be supplied with two infeeds, for example, a flat belt and a DRT (Dual Race Track) infeed to allow production to switch from ‘flat packing’ to ‘on edge’ packing for shelf-ready display packs.

Size changing is tool-less via hand-wheels and digital indicators.

The ZX600 Top Load Case Packer erects, loads, and closes cases within a very compact footprint, and utilises a six-axis robot via add on instruction; embracing full flexibility; the robot is also used to manipulate loading the collation and case transfer reducing complexity and mechanical assemblies. An integrated ‘on-demand’ glue system with remote glue pellet store and controlled via add on instruction.

The innovative routine for preconditioning the case allows minimal clearance between the product collation and the case providing material costs savings and maximizing pallet utilization. It also negates the need for an additional mechanical loading mask and associated size-change parts, reducing inventory, change-over times, and maintenance.

Wraparound case packing is an alternative to loading products into preformed cases or trays. Advantages that come from using this process are higher speed of operation and a minimal clearance between product and case.

The Bradman Lake range of wraparound case packers is a family of indexing machines consisting of 4 models ranging from a 2 station model capable of packing at 10 cases per minute up to a 6 station model that can produce up to 50 cases per minute. All models are capable of producing full wraparound cases, skeletal cases, low wall trays and high wall trays. Case designs incorporating tear off sections for shelf ready display packs can also be accommodated.

All models can be supplied with a dedicated infeed collator or robot to handle various product types, including cartons, cans and bottles.

Latest Development

Bradman Lake assists customer in expanding packaging capacity without adding real estate with a newly developed dual lane robotic six station wrap around case packer capable of up to 40 cases per minute.

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request