Flow Wrapping

Bradman Lake designs and manufactures modular and scalable horizontal flow wrapping systems that meet the most demanding environments and packaging needs. This approach provides end-users with future proof solutions, allowing progression to fully automated systems which reduce initial capital investment whilst increasing asset value. Whether you’re packaging food, pharmaceuticals, consumer goods, or other products, our advanced flow wrappers are designed to streamline your packaging process while ensuring optimal product presentation and protection.

Continuous innovation and development deliver systems combining the highest production rates with unrivaled operation reliability.

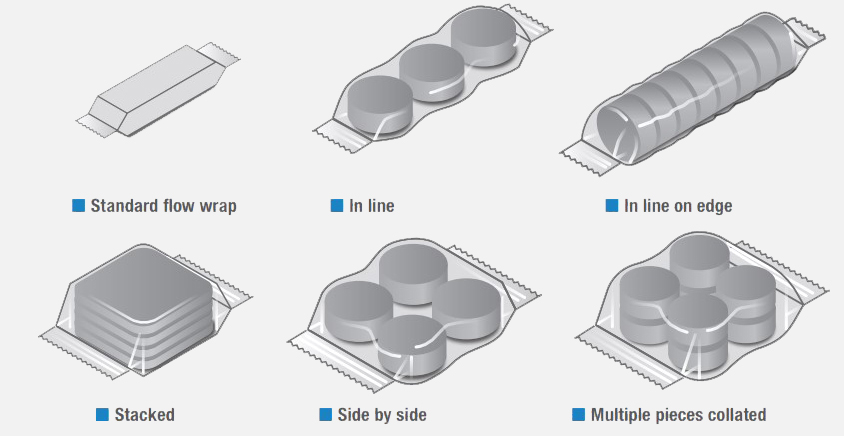

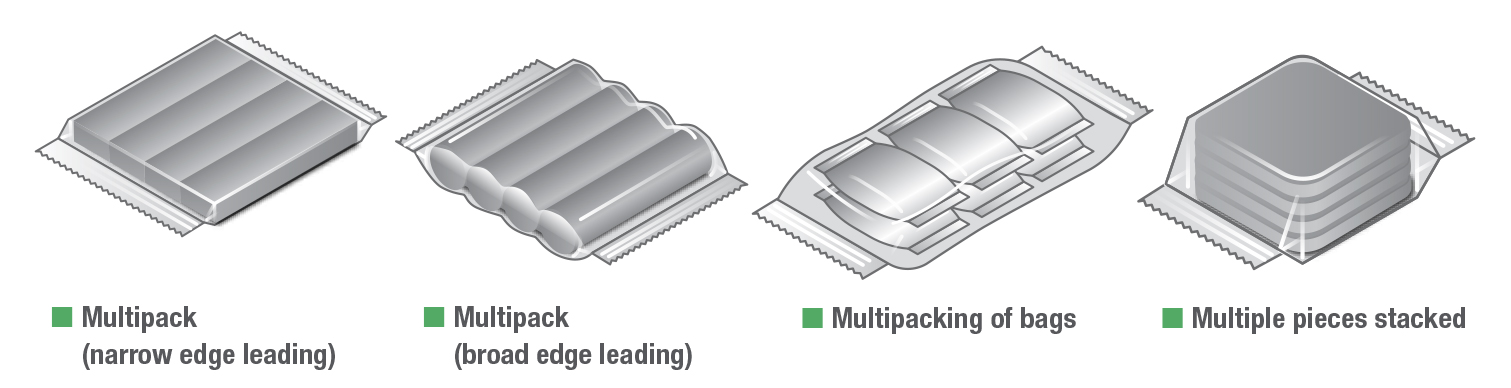

Packaging Styles

Bradman Lake provides manufacturers with a number of collation and multipack format options for wrapping individually wrapped products.

Flow Wrappers Models

The FT120 Flow Wrapper model is the latest version of this well-established electronic flow wrapping machine. Always at the leading edge of flow wrapping technology, the FT120 Flow Wrapper incorporates over 75 years of experience designing and building packaging machines and includes a multi-axis Allen Bradley servo control and motor package, PLC control system and man-machine interface.

Provides a wide range of collation and multipack format options.

A typical multipack flow wrapping system comprises a primary flow wrapper feeding a DRT robotic top loader that collates individual products and picks and places multiple collations into a secondary multi-pack flow wrapper infeed.

The FT120MP Multipack Flow Wrapping System can be seamlessly integrated with the VGR Vision Guided Robotics Feeder.

The operation of the biscuit-on-edge flow wrap machine is generally the same as the standard horizontal wrapper, but the product feed system and handling during the wrapping process are adapted to suit the biscuit-on-edge collation. The collation of biscuits is manually or automatically fed into the infeed of the BOE biscuit-on-edge flow wrapper, and is supported at the rear by the infeed carrier and the front by a spring-loaded finger. As the biscuits travel through the BOE flow wrapper, the front and rear support transfers to side support, ensuring the collation stays in place while the pack travels through the end seal jaws and is completely sealed. The side also supports automatically gusset the end seals.

The Distinctive Advantages of Bradman Lake’s Horizontal Flow Wrappers

The Bradman Lake FT Series Horizontal Flow Wrapping machines operate at the highest levels of efficiency, even in the most demanding environments.

The flow wrappers machines are simple to operate and maintain as well as being able to accommodate a wide range of product sizes with simple and quick changeover. A large memory in which size change parameters can be stored and retrieved for the rapid changeover of both flow wrapper and feeding systems is available.

Operator adjustable features without tools:

- End crimp dwell

- Film cut off length

- Product position in bag

- Print registration (if fitted)

Unique to Bradman Lake, it prevents misplaced products from jamming in the end seal jaws.

Automatic splicing is a standard feature on a system. A manual splice is also available for stand-alone machines.

Self-adhesive tape is applied to the wrapping material, which provides a more consistent method for opening the pack.

Maintains position of wrapping material presentation from the reel, providing increased efficiency and productivity whilst keeping material width to a minimum.

Utilises servo-driven reel mandrels which replace the mechanical braking system, used on high linear wrapping material speeds.

It provides a consistent transfer onto the discharge conveyor, therefore, ensuring a regular pitch between product when interfacing with downstream equipment.

Delivers a pre-selected count of wrapped products to aid the hand packing process.

For mounting various coders, which offers the customer flexibility to select their preferred brand.

The vacuum system removes empty flow wraps prior to discharge.

If no gap is detected between products on the infeed, the end seal jaws will not come together, and a long bag is formed that is rejected on the machine infeed. The machine does not stop production.

If no product is detected in the machine pitch, the end seal jaws simply wait for the next product. No empty pack is produced, so there is no wastage and the machine continue to run.

Machine versions capable of wrapping speeds up to 1200 packs per minute are available.

What does a typical fully automatic flow wrapping system include?

A flow wrapping system typically includes row conditioning, row feed station, product orientation, smart belt pressureless phase feeder and flow wrapper.

Ready to take the next step? Contact us today to discuss your flow wrapping needs and schedule a consultation with one of our packaging specialists. With Bradman Lake as your partner, you can achieve efficient, reliable, and cost-effective packaging solutions that drive success for your business.

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request