Baked Goods

We champion major advancements in technological development to meet and exceed the increased demands for speed and accuracy in the production of bakery products throughout the world, including bread, biscuits, cakes, snacks and nutritional bars.

Bradman Lake's Packaging Systems For Baked Products

Bradman Lake’s integrated packaging technologies deliver innovative, turnkey solutions to provide increased system performance, higher speeds and efficiency, reduction of waste in both product and wrapping materials as well as decreased

changeover times and reduced labour costs.

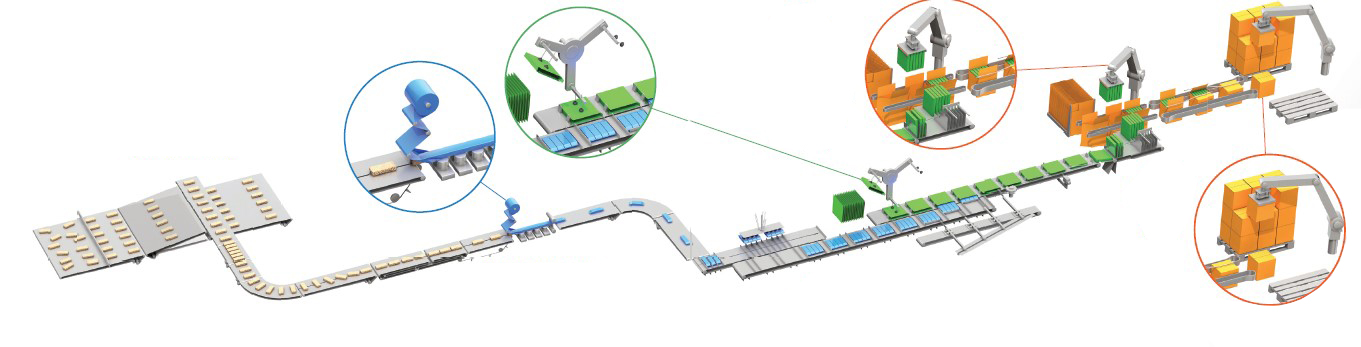

This fully automatic bar packaging system illustrates the Bradman Lake ‘single source solution’ capability; From Process to Pallet.

Additional features which can be easily incorporated, include full line management control and consumer protection packages.

The bar packing system includes:

Primary Packaging: Row conditioning, row feed station. product orientation, smart belt pressureles phase feeding and flow wrapping.

Secondary Packaging: Racetrack flow wrap collating, robotic picking and placing and end load cartoning.

Tertiary Packaging: Race track carton collating, case erecting, robotic case loading, case closing, robotic palletising.

Other configurations are available based on the customers’ requirements.

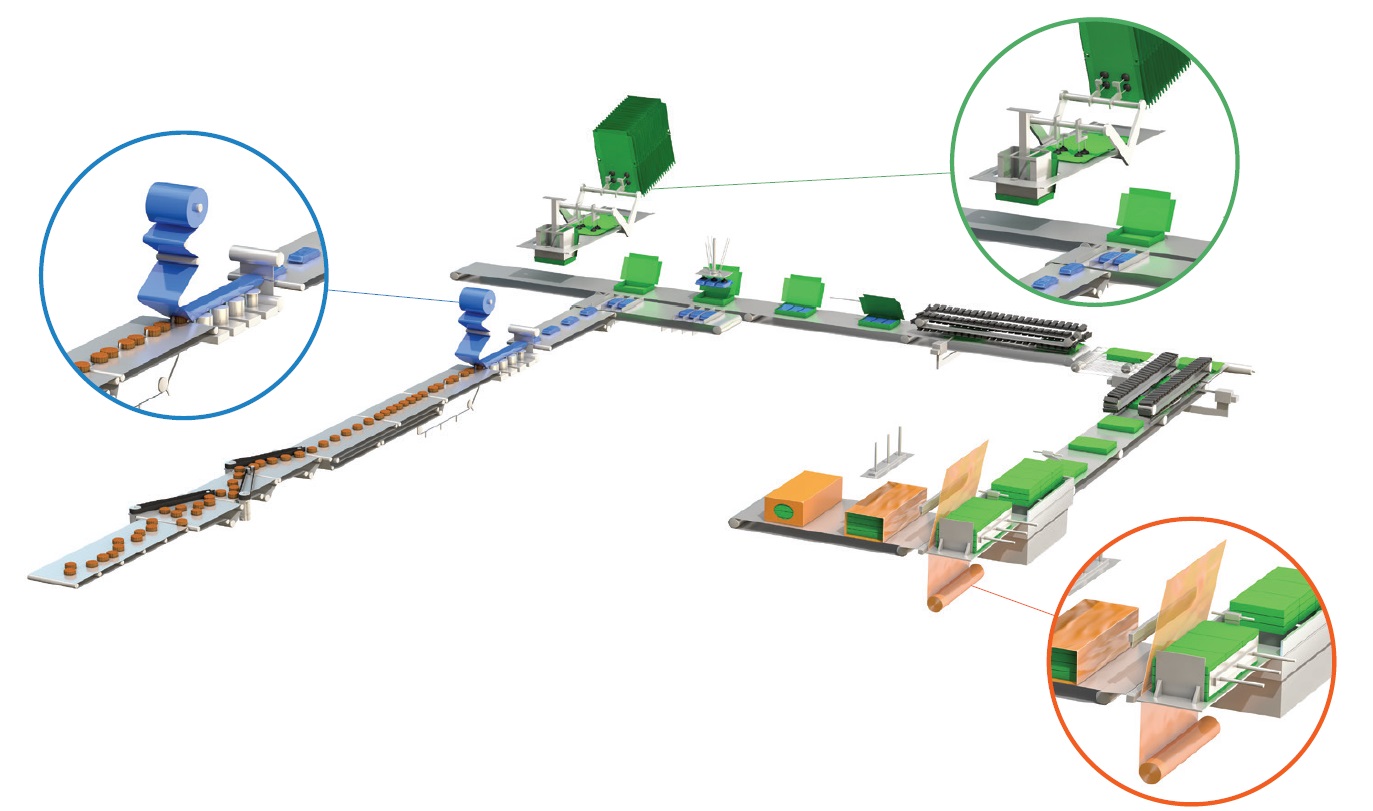

The pie packing system will take product from the chiller through each packaging process and deliver a shrink wrapped collation of cartons ready for shipping. A pressureless phase feeding system collates the product to be wrapped using either hot or cold seal material to provide the level of sealing and protection required. Cartons are formed using either a lock or hot glue system and the flow wrapped product is robotically loaded in the required ‘layer and collation’ format. The lids of the cartons are then glued closed using Bradman Lake’s unique ‘flexible carton control’ technology and presented to a collation unit that will form the final product collation to be sealed in a shrink wrap material.

The pie packing system includes:

Primary Packaging: Product orientation, smart belt and flow wrapping.

Secondary Packaging: Race track collating, carton erecting, robotic pick and

place loading and carton closing.

Tertiary Packaging: Carton collation, and shrink wrapping.

Other configurations are available based on the customers’ requirements.

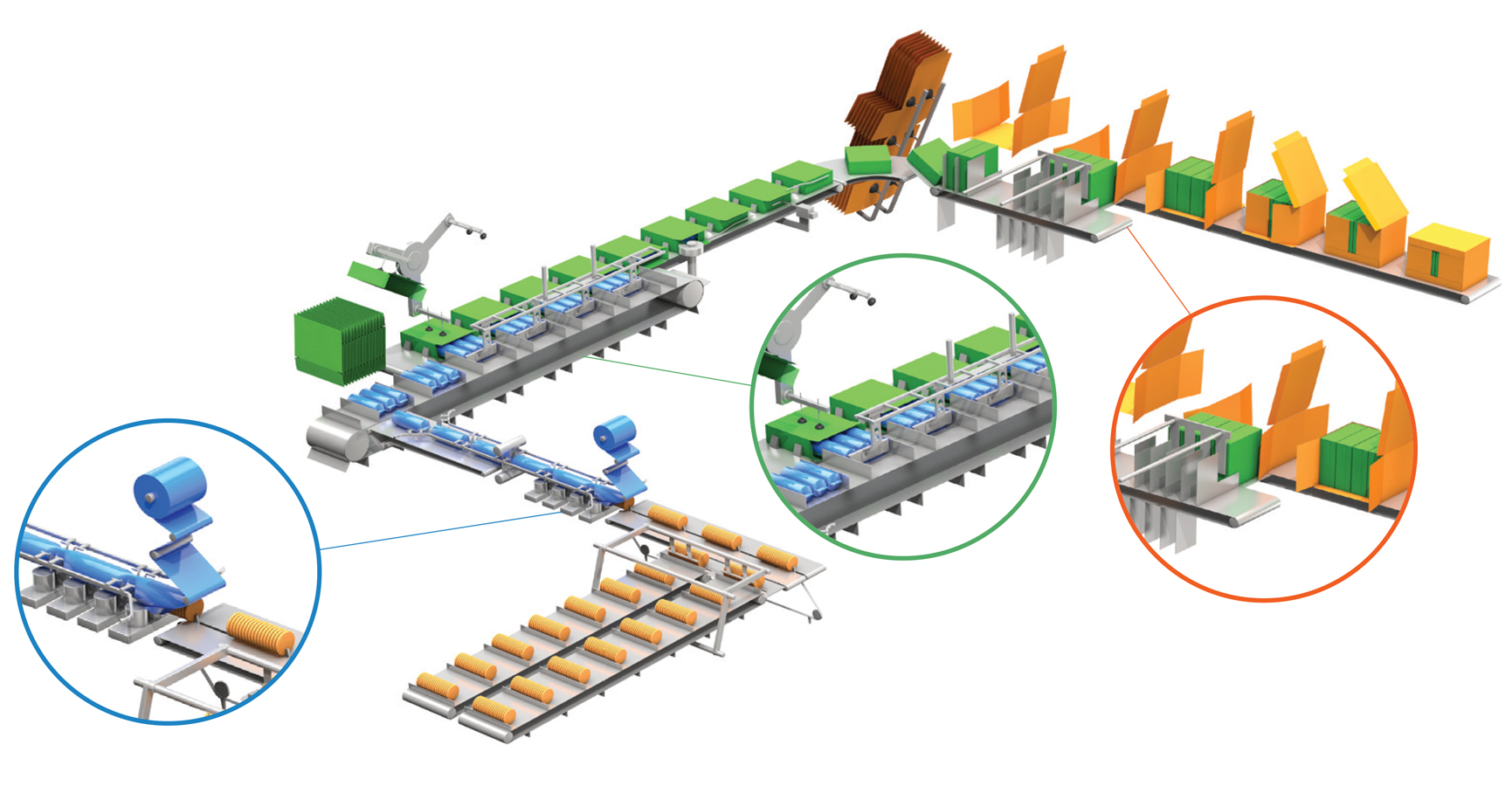

Bradman Lake biscuit packing systems utilize proven technology. The biscuit collations are fully supported through the flow wrapping process. To minimize product damage and maintain collation form, Race Track

technology collates the required pack count to end-load into the carton. The wraparound case packer allows for material savings via flat blanks and skeletal case formats.

The biscuit packing system includes:

Primary Packaging: Product orientation, collation and on-edge’ flow wrapping.

Secondary Packaging: Race track collating and end load cartoning.

Tertiary Packaging: Racetrack carton orientation and collation and case packing.

Other configurations are available based on the customers’ requirements.

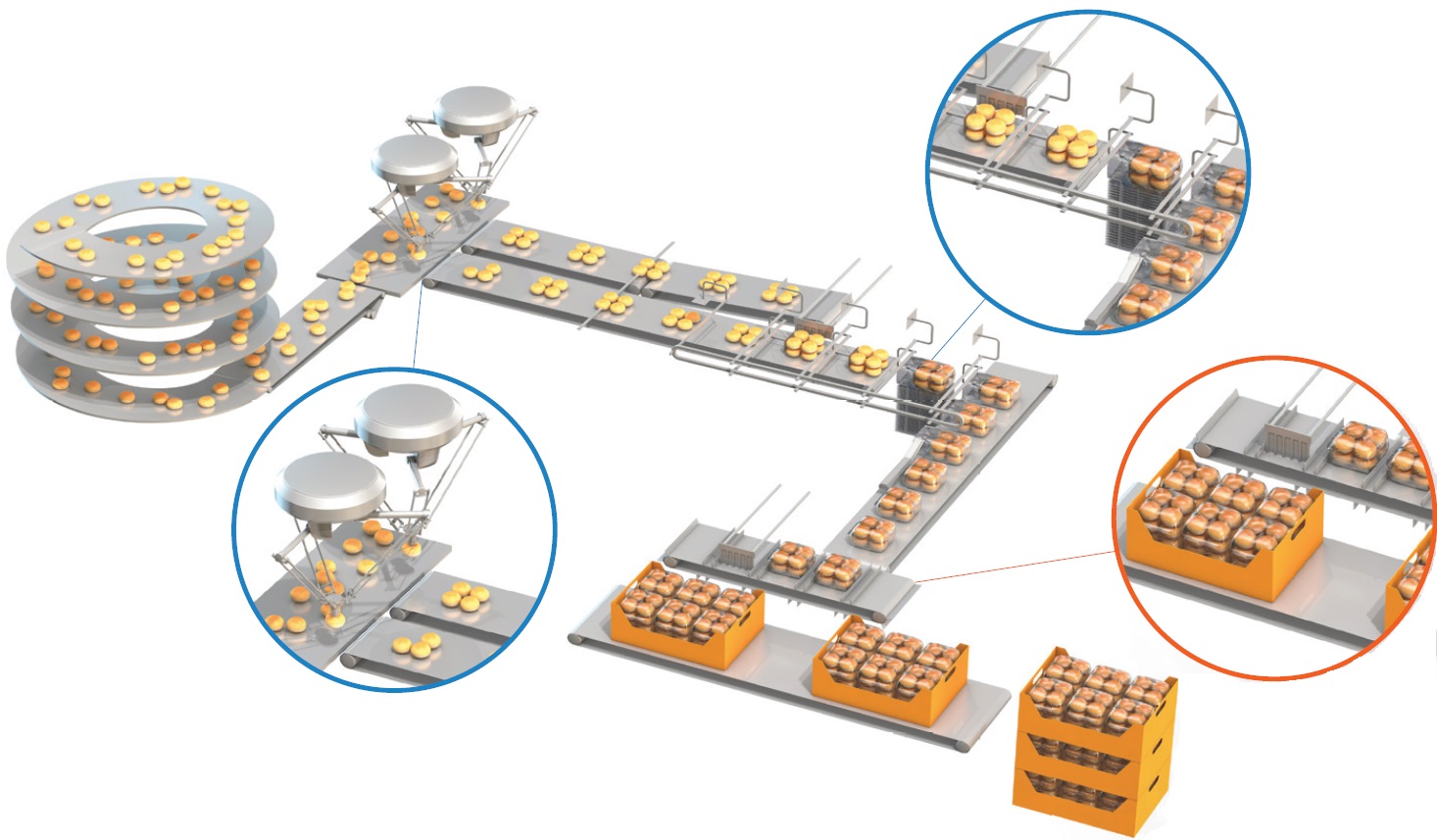

Designed for the Plant Bakery looking to fully automate collation and product inspection, Bradman Lake are able to utilise the latest in guided robot technology to collate and slice bread rolls into bags. With the introduction of product buffering, stored product can be reintroduced into the system during normal production operation, thus minimising downtime, product waste while increasing plant productivity and efficiency. The packaged product is automatically loaded into baskets using Bradman Lake’s proven basket loading system. This takes the packaging of bread rolls to new levels of automation and sophistication.

The bread packing system includes:

Primary Packaging: Vision guided robotics, slicing, collation and bagging.

Tertiary Packaging: Collation and basket loading.

Other configurations are available based on the customers’ requirements.

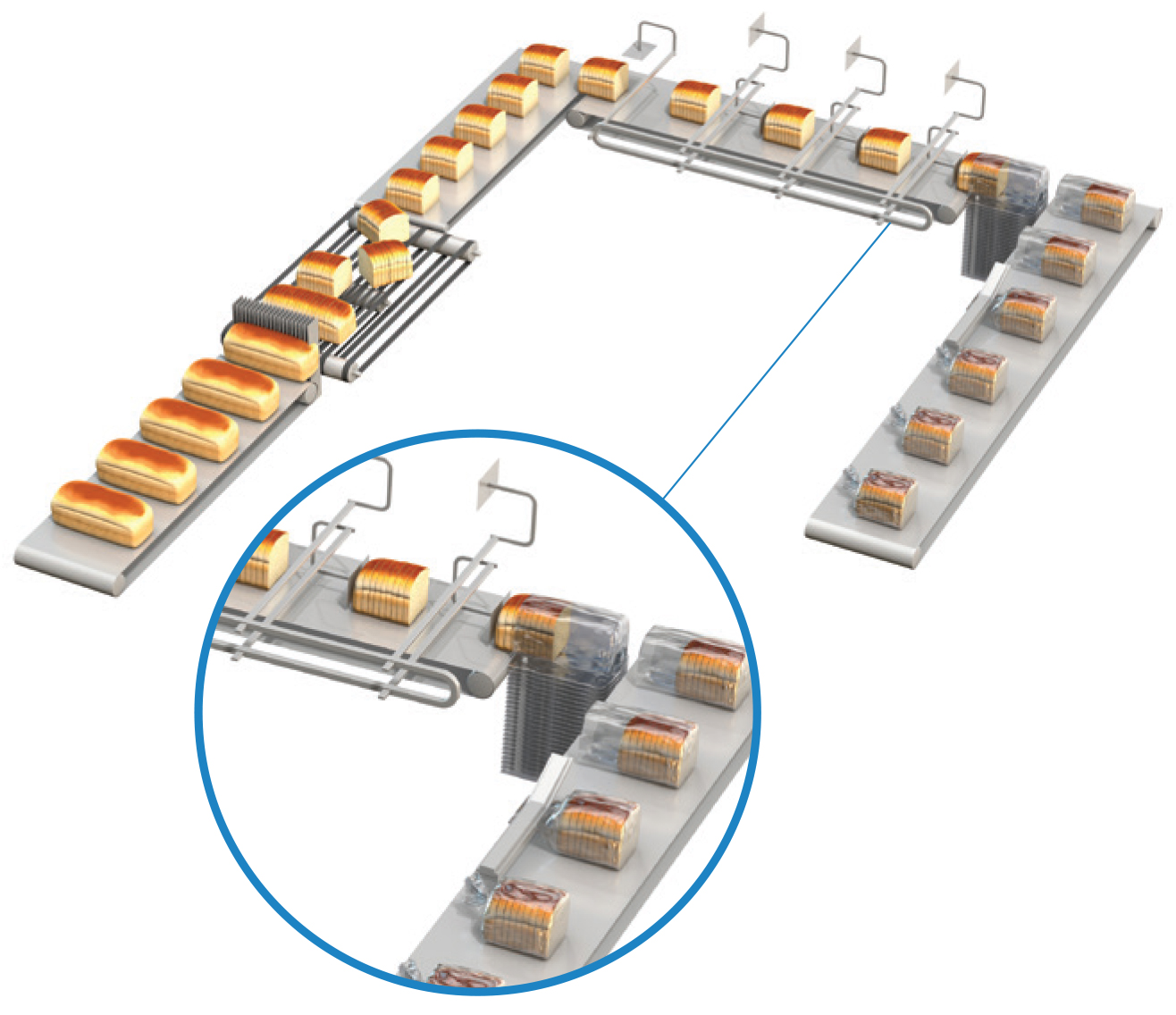

Bradman Lake bread packing systems with synchronizing infeeds allow tinned and artisan loaves to be sliced, bagged and closed. Whole

loaves can also be split and one half turned through 180 degrees before bagging and closing. Different styles of pusher faces allow us to

accommodate the many different styles of bread in the market.

The bread packing system includes:

Primary Packaging: Slicer, orientation and bagger.

Other configurations are available based on the customers’ requirements.

Bradman Lake assists customer in expanding packaging capacity without adding real estate

Due to ever growing demand, Pukka is expanding retail production by introducing a new high speed, flexible packaging line into their manufacturing facility in Leicestershire. Bradman Lake was tasked with unlocking the challenge of feeding a new high speed packaging leg from two existing process lines, with the ability to pack faster due to increased demands for a smaller SRP case collation.

Working alongside the customer, Bradman Lake developed a new layout providing new bridging transport conveyors and newly developed small footprint packaging machines.

Bradman Lake Automates Bagel Packaging with Newly Developed On-Edge Collator

Automating Packaging for Diamond Bakery Cookies and Crackers in Hawaii

Bradman Lake, a leading provider of packaging solutions, is proud to announce that its SL903 End Load Cartoning Machine is now in production at Diamond Bakery in Hawaii. This partnership was formed after Bradman Lake’s advanced equipment caught the attention of Diamond Bakery executives at a recent trade show.

Get in touch

Contact us today for a free consultation, quote, and to request our brochure specifically designed for the bakery industry.