Chilled and Frozen Foods

All brands within Bradman Lake have extensive experience in the supply of machinery to the chilled and frozen foods sector. Meat, Fish, Vegetable or Ice Cream products, Bradman Lake can provide machinery to meet specifications demanded by each industry. Wipe down to full stainless-steel construction with wash down capability, machine variations are available to suit specific environmental operating conditions.

Bradman Lake's Packaging Systems For Frozen Foods Products

Bradman Lake’s integrated packaging technologies deliver innovative, turnkey solutions to provide increased system performance, higher speeds and efficiency, reduction of waste in both product and wrapping materials as well as decreased changeover times and reduced labour costs.

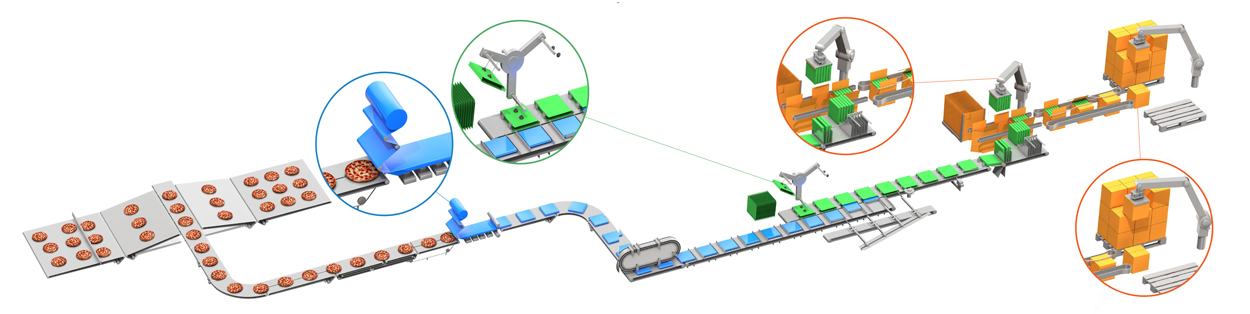

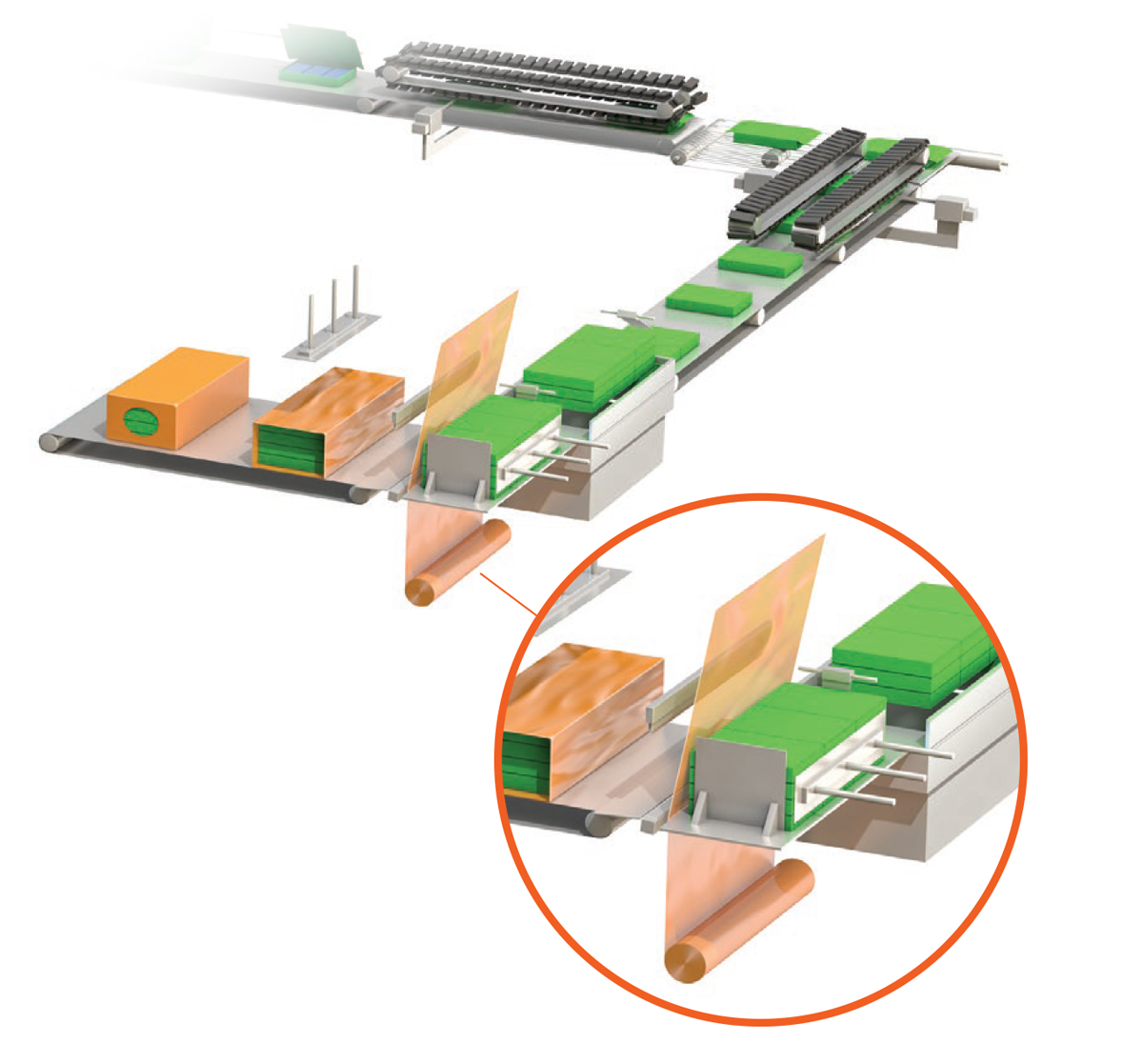

This fully automatic packaging system illustrates the Bradman Lake ‘single source solution’ capability. Additional features which can be easily incorporated, include full line management control and consumer protection packages.

The pizza packing system includes:

Primary Packaging: Row conditioning, row feed station. product orientation, smart belt pressureles phase feeding and flow wrapping.

Secondary Packaging: Race track flow wrap collating, intelligent motion loading and end load cartoning.

Tertiary Packaging: Race track carton collating, case erection, robotic case loading, case closing, robotic palletising.

Other configurations are available based on the customers’ requirements.

The packing system will take product from the oven and cooling tunnel, through each packaging process and deliver a collation of cases onto a pallet ready for shipping. Product is orientated, then a pressureless phase feeding system collates the product to be wrapped using either hot or cold seal material to provide the level of sealing and protection required. Cartons are formed using either a lock or hot glue system and the flow wrapped product is robotically loaded in the required ‘layer and collation’ format. The lids of the cartons are then glued closed using Bradman Lake’s unique ‘flexible carton control’ technology and presented to a collation unit that will form the final collation to be robotically loaded into cases and then sealed using hot glue or tape. Sealed cases are robotically loaded on a pallet, with slip sheets between them for extra protection.

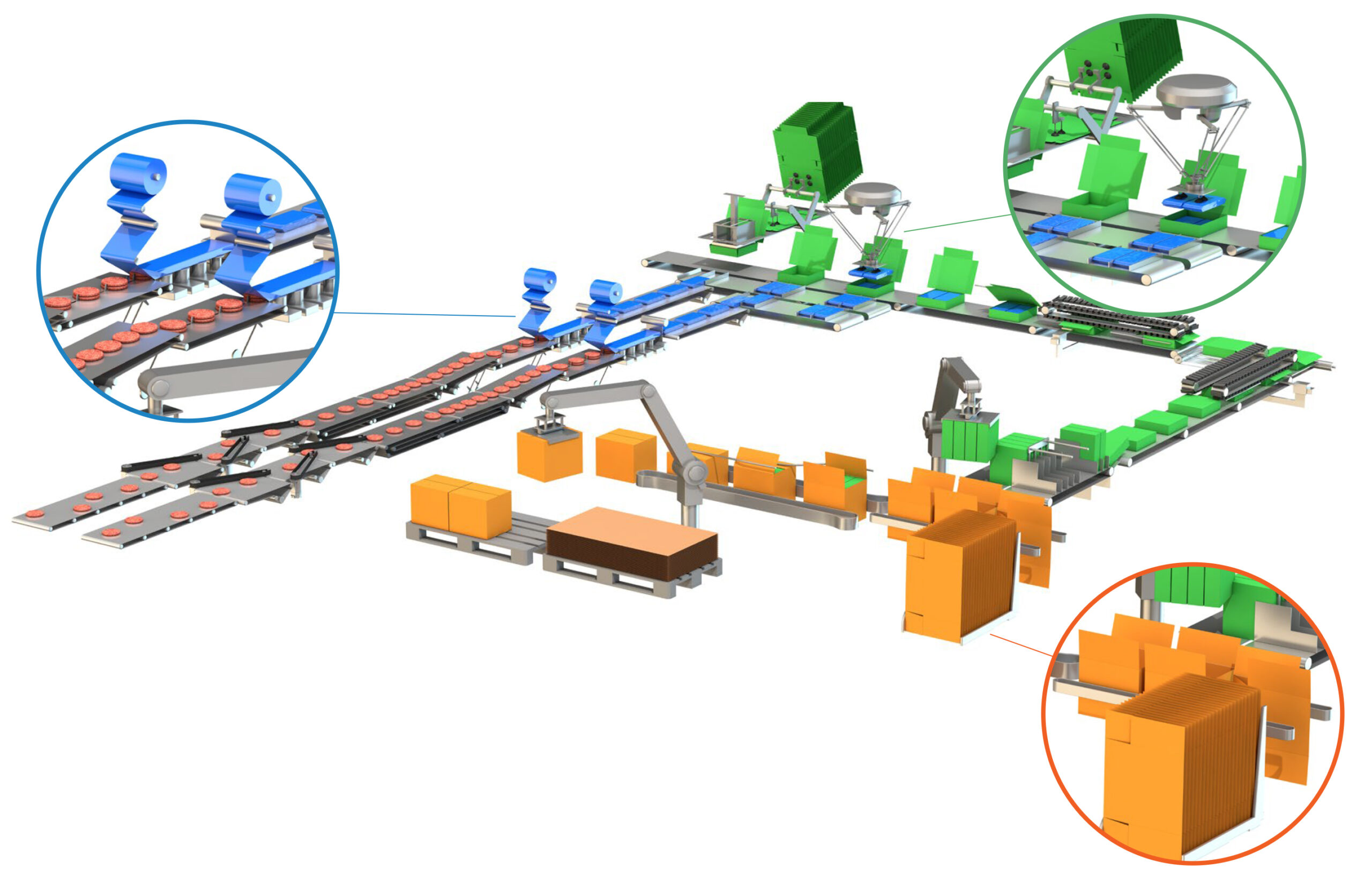

The frozen burger packing system includes:

Primary Packaging: Product orientation, smart belt and flow wrapping.

Secondary Packaging: Race track collating, carton erection, robotic pick and place loading and carton closing.

Tertiary Packaging: Race track carton, collating, case erection, robotic case loading, case closing, robotic palletising and slip-sheet insertion.

Other configurations are available based on the customers’ requirements.

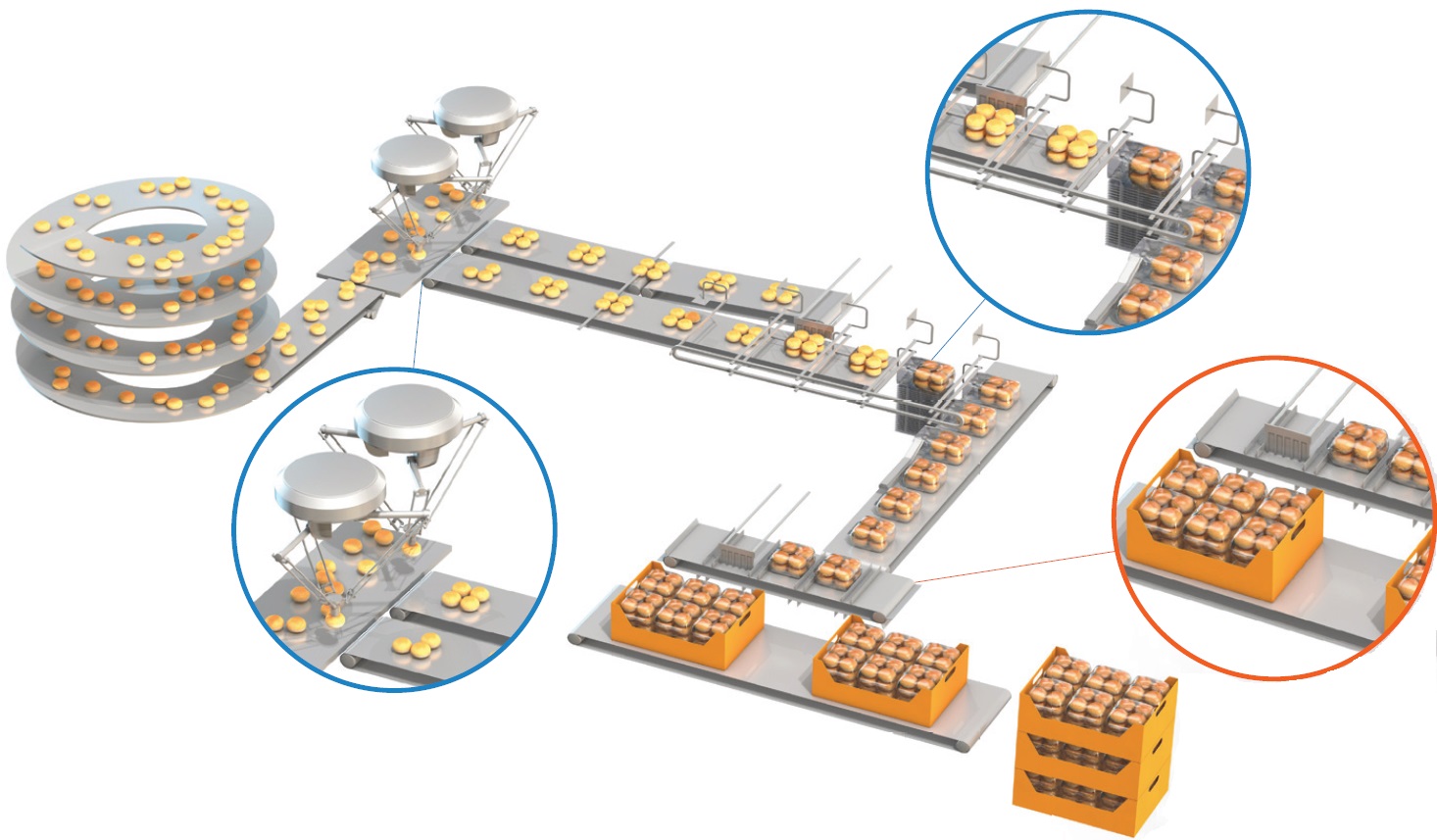

Designed for the Plant Bakery looking to fully automate collation and product inspection, Bradman Lake is able to utilise the latest in guided robot technology to collate and slice bread rolls into bags. With the introduction of product buffering, stored product can be reintroduced into the system during normal production operation, thus minimising downtime, product waste while increasing plant productivity and efficiency. The packaged product is automatically loaded into baskets using Bradman Lake’s proven basket loading system. This takes the packaging of bread rolls to new levels of automation and sophistication.

The chilled bread roll packing system includes:

Primary Packaging: Vision guided robotics, slicing, collation and bagging.

Tertiary Packaging: Collation and basket loading.

Other configurations are available based on the customers’ requirements.

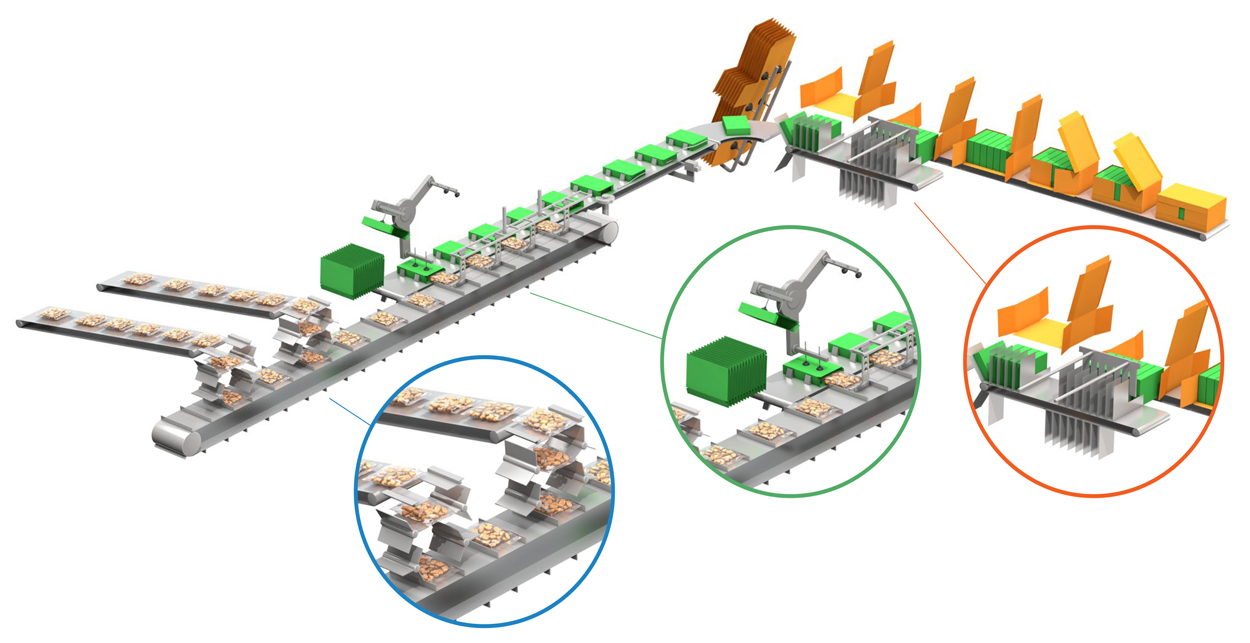

Bradman Lake packing systems utilise proven technology. The collations are fully supported through the twin cascade loaders. To minimise product damage and maintain collation form, Race Track technology collates the required pack count to end-load into the carton. The wraparound case packer allows for material savings via flat blanks and skeletal case formats.

The bag-in-box packing system includes:

Secondary Packaging: Twin cascade loader, racetrack collating and end load cartoning.

Tertiary Packaging: Racetrack carton orientation and collation and wrap around case packing.

Other configurations are available based on the customers’ requirements.

The shrink wrapper uses an ‘over wrap’ principle to wrap the product. The machine employs a film application method that takes film from a single reel, cuts it to length, and then applies it around the product with an overlap underneath the pack. This overlap is sealed as the pack passes through a heat tunnel. Apart from the higher speeds which are achievable, the absence of a conventional sealing jaw leads to lower maintenance. The film which is accurately cut to length, facilitates the use of registered printed film.

The shrink-wrapping packing system includes:

Tertiary Packaging: Carton collation and shrink wrapping.

Other configurations are available based on the customers’ requirements.

Bradman Lake proves to be a winner in Caustic Wash-down requirements

When it comes to packaging processed meat products it has to meet and exceed industry mandated hygiene requirements. Therefore, when it came to selecting a new carton lid closer to close their 3-flap style lid covers Monogram had to acquire a machine that can withstand caustic wash-down.

Difficult Automation Made Easy for Frozen Foods

Using carton designs originated by Bradman Lake, Murrys switched from expensive to produce pre glued and folded cartons to less expensive flat blank versions which are lock formed on Bradman Lake HS double head formers.

The automatic bag loader to pick and place the bags of product into these cartons was developed by Bradman Lake in partnership with Rockwell/Allen Bradley. After the cartons are loaded and the bags are placed inside the base, the package is then transferred to Bradman Lake’s IL120 carton closer.

Get in touch

Contact us today for a free consultation, quote, and to request our brochure specifically designed for the chilled and frozen foods industries.