Dry Foods

The packaging solutions offered by the Bradman Lake Group are widely used by the global dry food industries worldwide.

Their exceptional performance and reliability is well proven in the packaging of cereals, tea, coffee, spices, powdered milk, soup products, sugar, pasta, pet foods and other similar products.

Bradman Lake's Packaging Systems For Dry Foods

Bradman Lake’s integrated packaging technologies deliver innovative, turnkey solutions to provide increased system performance, higher speeds and efficiency, reduction of waste in both product and wrapping materials as well as decreased changeover times and reduced labour costs.

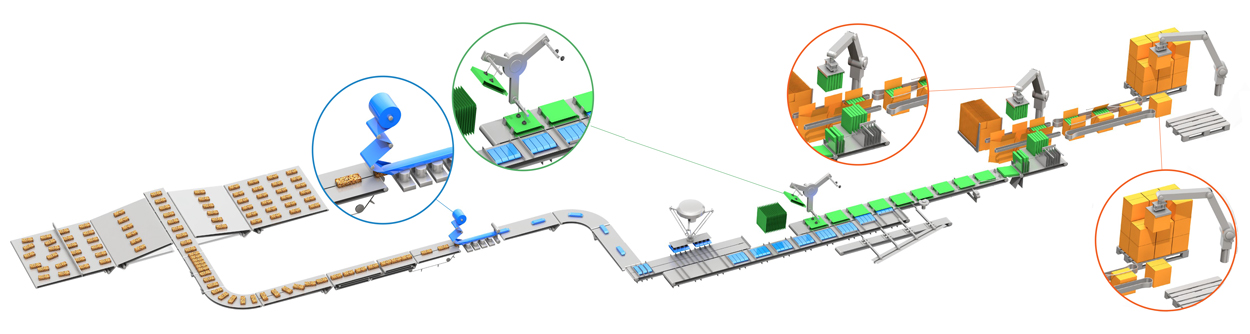

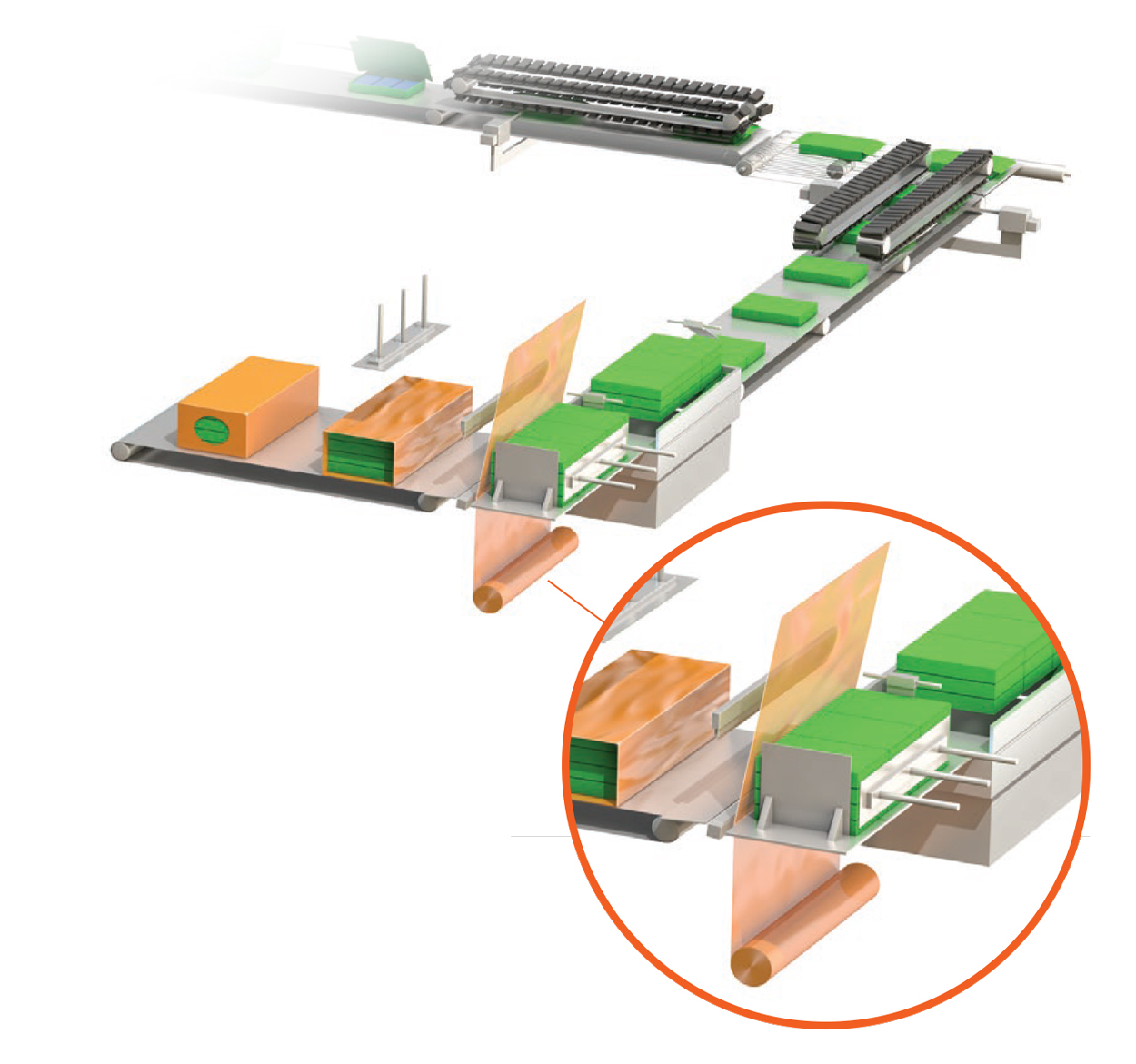

This fully automatic bar packaging system illustrates the Bradman Lake ‘single source solution’ capability. Additional features which

can be easily incorporated, include full line management control and consumer protection packages.

The bar packing system includes:

Primary Packaging: Row conditioning, row feed station, product orientation, smart belt pressureless, phase feeding and flow wrapping.

Secondary Packaging: Race track flow wrap collating, robotic picking and placing and end load cartoning.

Tertiary Packaging: Race track carton collating, case erection, robotic case loading, case closing, robotic palletising.

Other configurations are available based on the customers’ requirements.

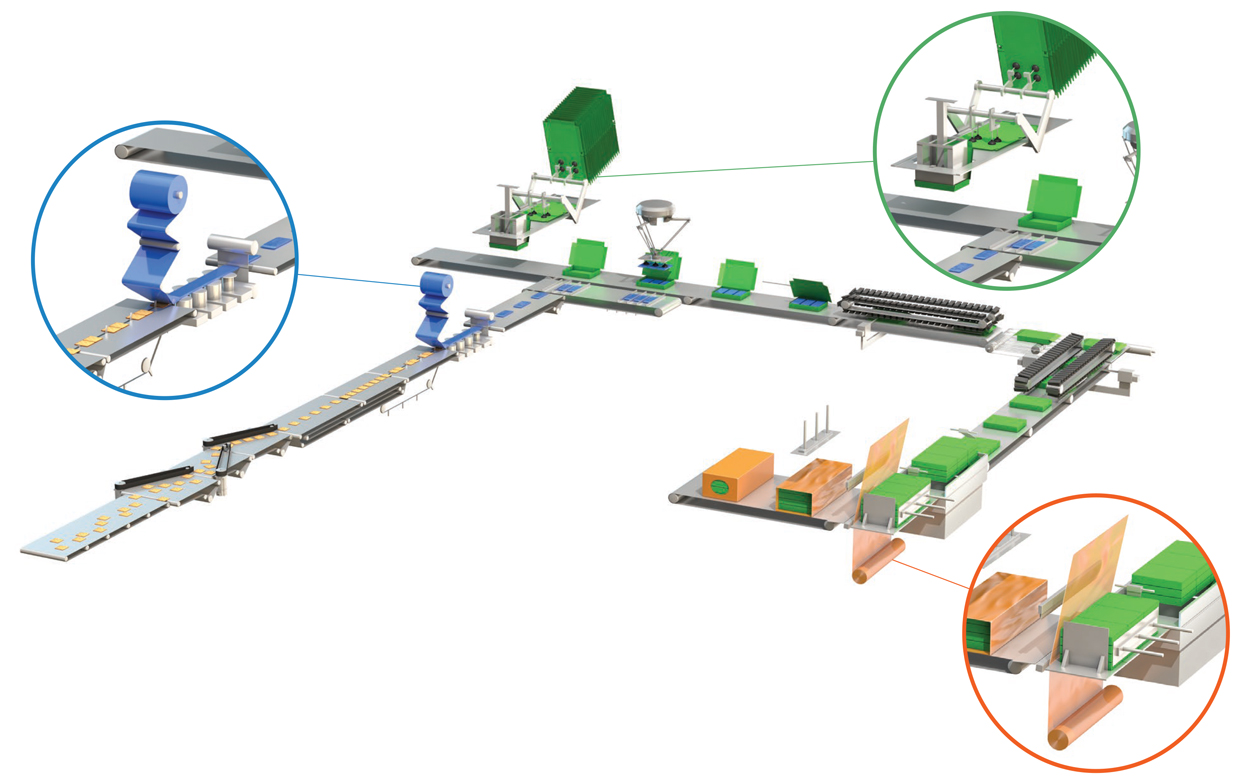

The cracker system will take product from the chiller through each packaging process and deliver a shrink wrapped collation of cartons ready for shipping. A pressureless phase feeding system collates the product to be wrapped using either hot or cold seal material to provide the level of sealing and protection required.

Cartons are formed using either a lock or hot glue system and the flow wrapped product is robotically loaded in the required ‘layer and collation’ format. The lids of the cartons are then glued closed using Bradman Lake’s unique ‘flexible carton control’ technology and presented to a collation unit that will form the final product collation to be sealed in a shrink wrap material.

The cracker packing system includes:

Primary Packaging: Product orientation, smart belt and flow wrapping.

Secondary Packaging: Race track collating, carton erection, robotic pick and

place loading and carton closing.

Tertiary Packaging: Carton collation and shrink wrapping.

Other configurations are available based on the customers’ requirements.

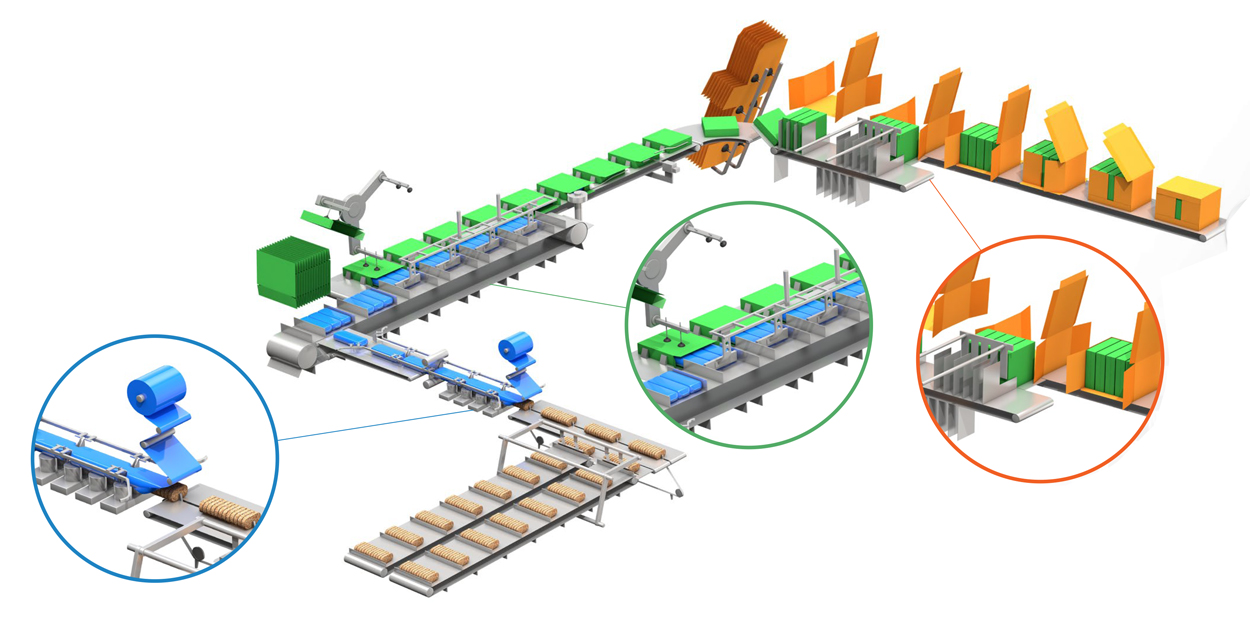

Bradman Lake on-edge packing systems utilise proven technology. The collations are fully supported through the flow wrapping process. To minimise product damage and maintain collation form, Race Track technology collates the required pack count to end-load into the carton. The wraparound case packer allows for material savings via flat blanks and skeletal case formats.

The on-edge packing system includes:

Primary Packaging: Product orientation, collation and ‘On Edge’ flow wrapping.

Secondary Packaging: Race track collating and end load cartoning.

Tertiary Packaging: Race track carton orientation and collation and case packing.

Other configurations are available based on the customers’ requirements.

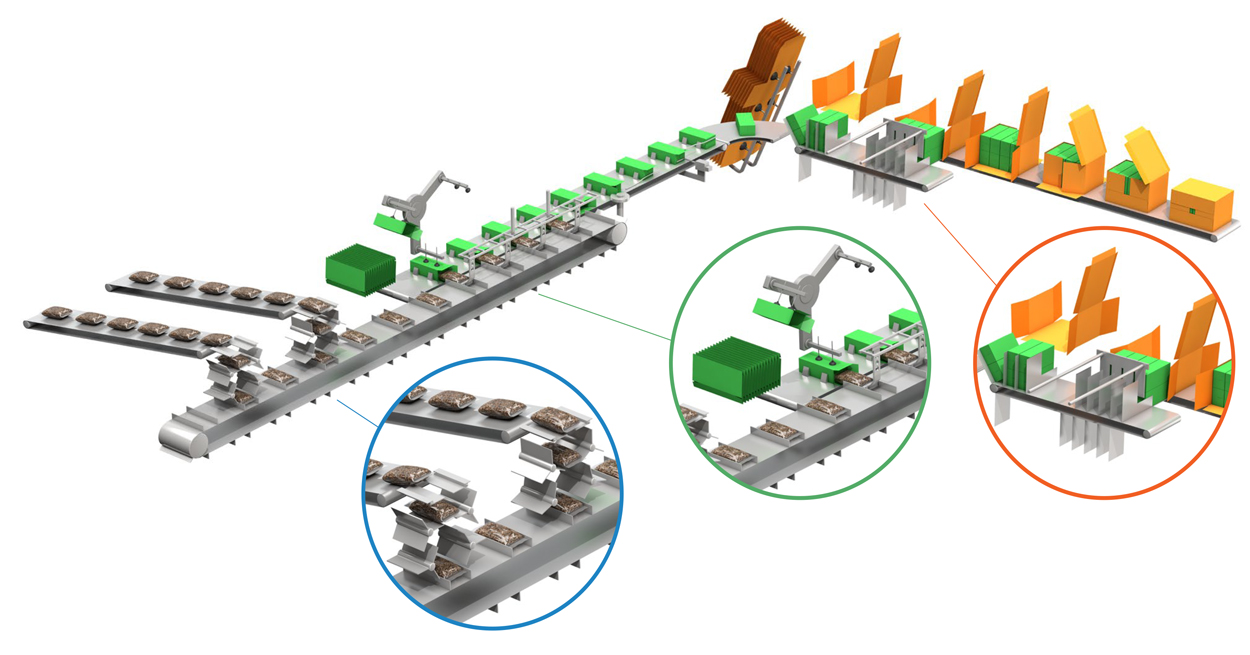

Bradman Lake packing systems utilise proven technology. The collations are fully supported through the twin cascade loaders. To minimise product damage and maintain collation form, Race Track technology collates the required pack count to end-load into the carton. The wraparound case packer allows for material savings via flat blanks and skeletal case formats.

The tea packing system includes:

Secondary Packaging: Twin cascade loader, race track collating and end load cartoning.

Tertiary Packaging: Race track carton orientation and collation and wrap-around case packing.

Other configurations are available based on the customers’ requirements.

The shrink wrapper uses an ‘over wrap’ principle to wrap the product. The machine employs a film application method that takes film from a single reel, cuts it to length, and then applies it around the product with an overlap underneath the pack. This overlap is sealed as the pack passes through a heat tunnel. Apart from the higher speeds which are achievable, the absence of a conventional sealing jaw leads to lower maintenance. The film which is accurately cut to length, facilitates the use of registered printed film.

The shrink wrapping packing system includes:

Tertiary Packaging: Carton collation and right-angle shrink wrapping.

Other configurations are available based on the customers’ requirements.

How Bradman Lake helped Tea manufactures to achieve their goals?

Tea is the most widely consumed beverage in the world next to water. The process of handling this delicate plant from harvesting to packaging cannot be overemphasized as it decides the level of tea quality in the consumer’s cup. The Bradman Lake Group has acquired extensive experience in the most recent packaging techniques required for handling and packing tea products.

Examples of tea packaging: Bag-in-box , flow wrapped tea bags, flow wrapped trays, flip top caddy style carton, gable top carton, shelf-ready cases, shrink wrapped cartons and shrink wrapped trays.

Get in touch

Contact us today for a free consultation, quote, and to request our brochure specifically designed for the dry food industry.