Pharma and Healthcare

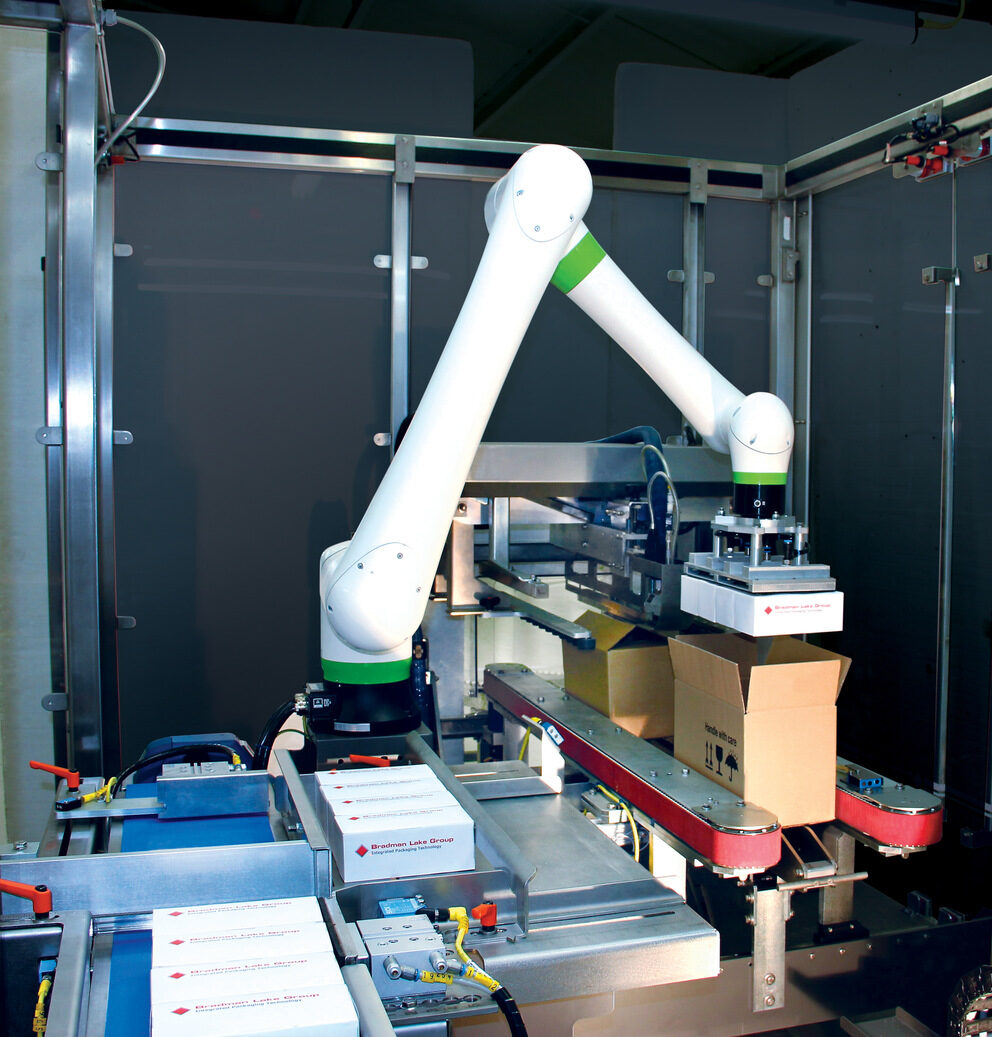

Bradman Lake has designed and manufactured packaging machines and systems to meet the specific needs of the pharmaceutical and healthcare industries.

We have a portfolio of collators for glass and plastic bottles and irregular shaped containers and devices for the control of unstable products. A wide variety of essential and everyday products in the home are handled by our systems, including many major brand names in a variety of international markets.

Bradman Lake's Packaging Systems For Pharma and Healthcare

Bradman Lake’s integrated packaging technologies deliver innovative, turnkey solutions to provide increased system performance, higher speeds and efficiency, reduction of waste in both product and wrapping materials as well as decreased changeover times and reduced labour costs.

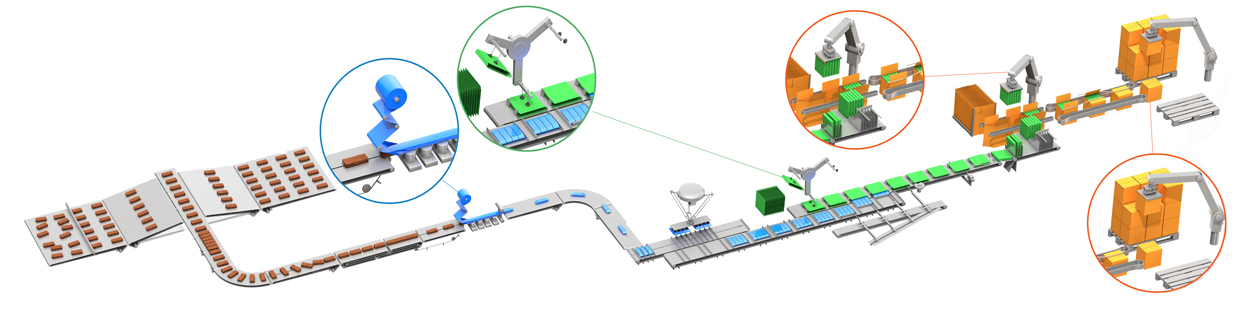

This fully automatic bar packaging system illustrates the Bradman Lake ‘single source solution’ capability. Additional features which

can be easily incorporated, include full line management control and consumer protection packages.

The bar packing system includes:

Primary Packaging: Row conditioning, row feed station, product orientation, smart belt pressureless, phase feeding and flow wrapping.

Secondary Packaging: Race track flow wrap collating, robotic picking and placing and end load cartoning.

Tertiary Packaging: Race track carton collating, case erection, robotic case loading, case closing, robotic palletising.

Other configurations are available based on the customers’ requirements.

Bradman Lake packing systems utilise proven technology. To minimise product damage and maintain collation form, Race Track technology collates the required pack count to end-load into the carton. The wraparound case packer allows for material savings via flat blanks and skeletal case formats into cases and then sealed using hot glue or tape. Sealed cases are robotically loaded on a pallet, with slip sheets between them for extra protection.

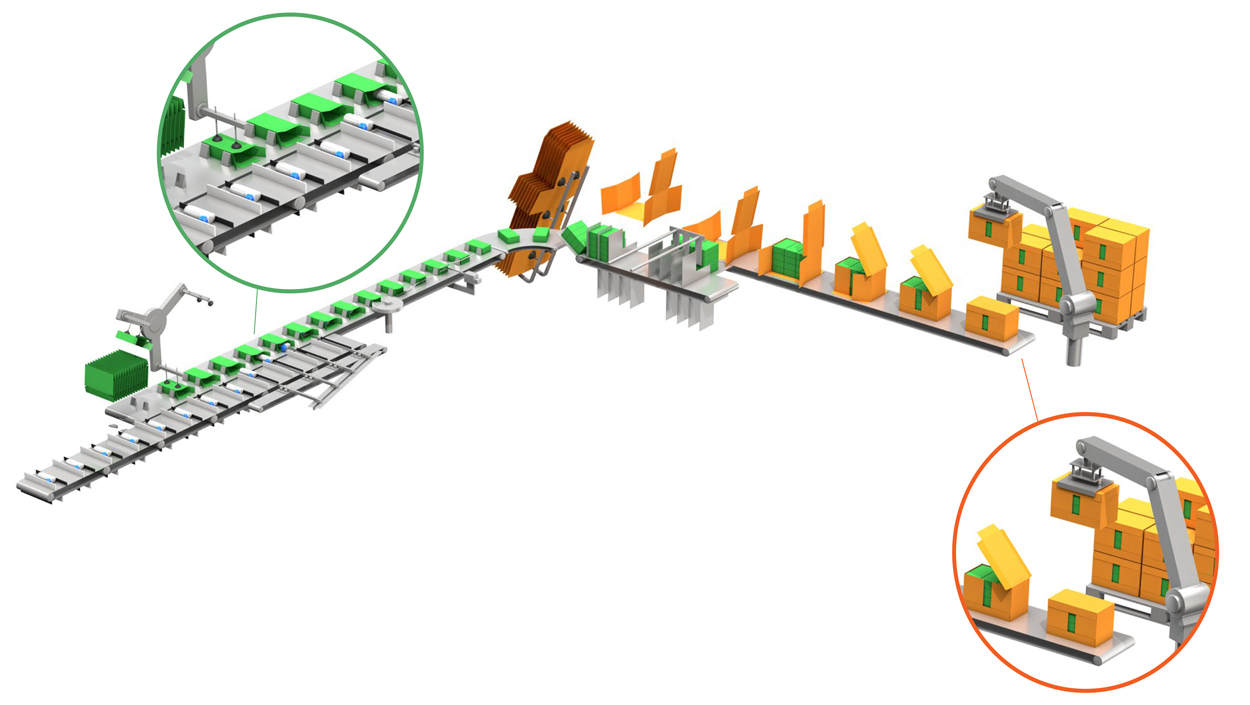

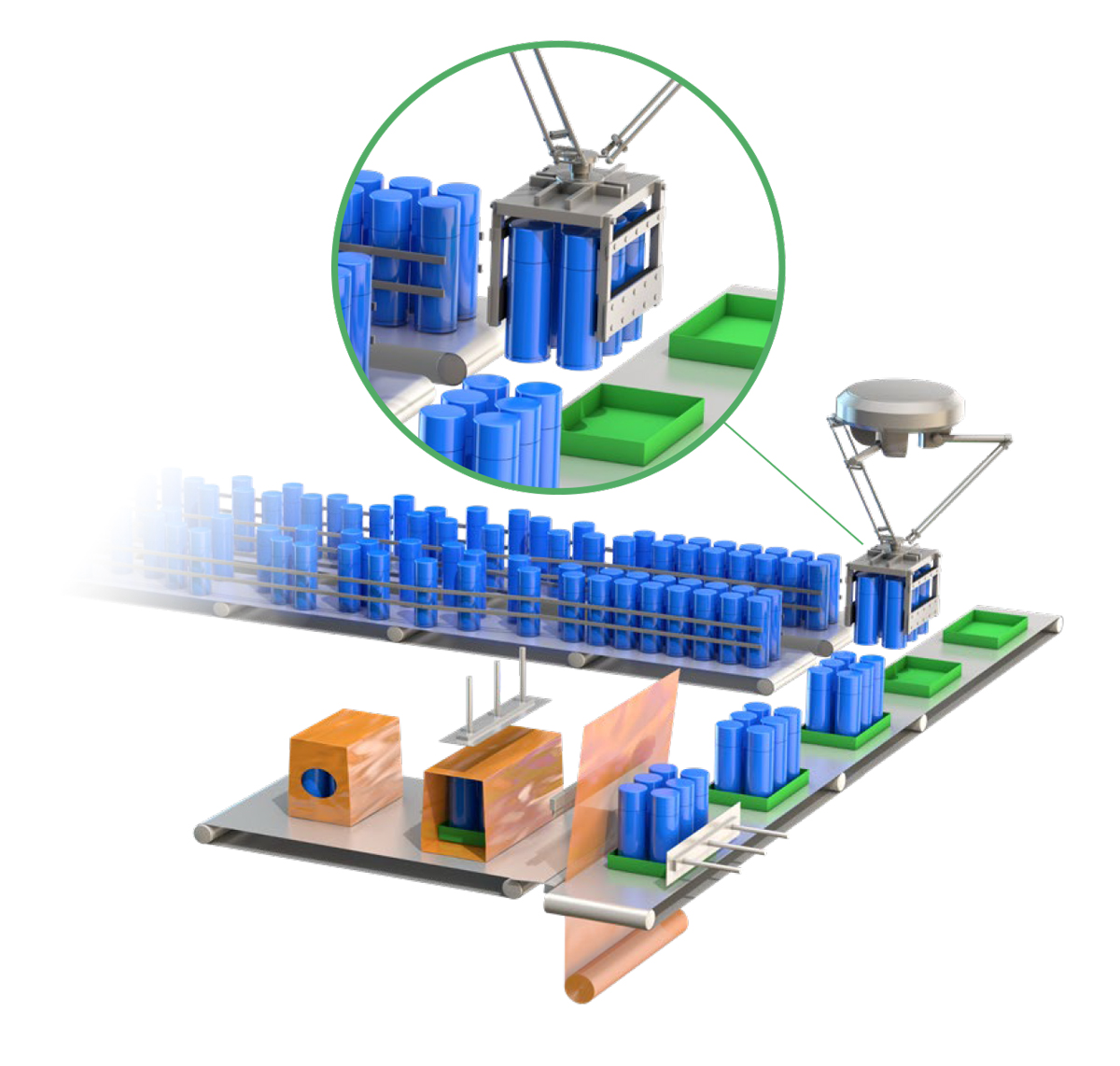

The inhaler packing system includes:

Secondary Packaging: Race track flow wrap collating and end load cartoning.

Tertiary Packaging: Race track carton orientation and collating, case packing and pallestising.

Other configurations are available based on the customers’ requirements.

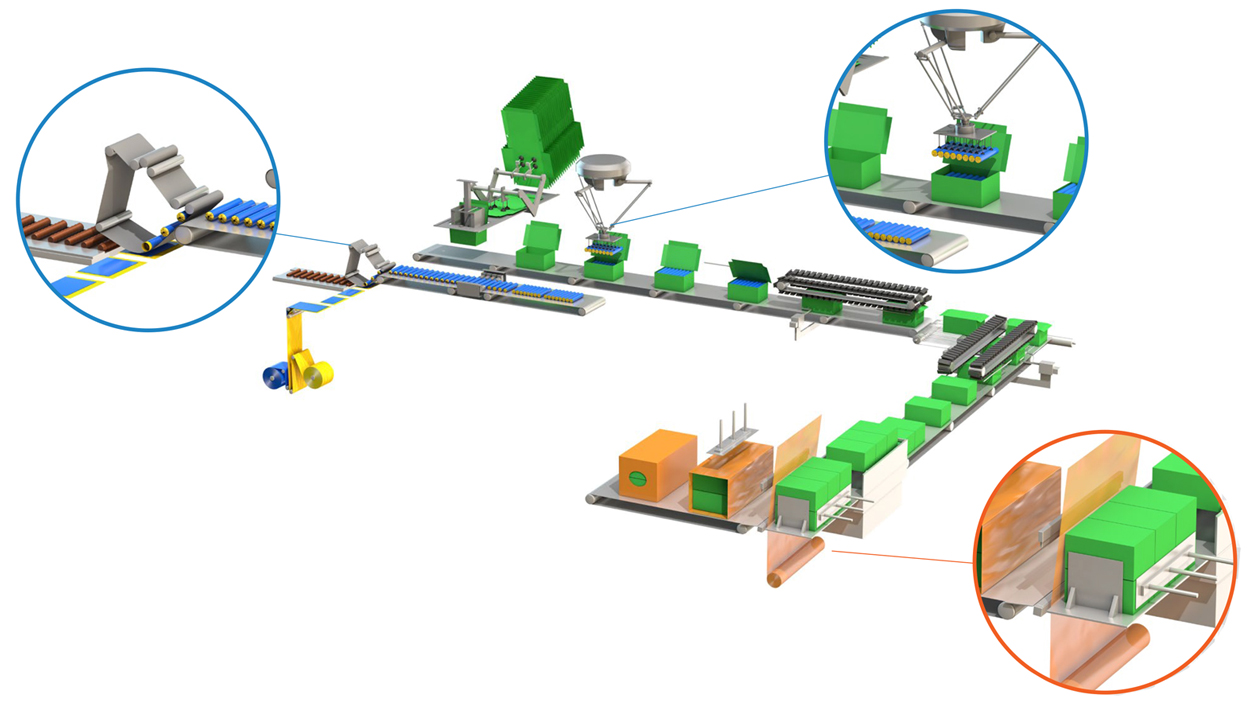

It is a simple and versatile system designed to quickly and effectively package small round, square, and rectangular confectionery items. It uses a rolling head belt wrapping principle to ensure consistent wrapping and secure product containment. Packs can be produced with either single overall wraps or overall wraps with outer label.

Cartons are formed using either a lock or hot glue system and the roll wrapped product is robotically loaded in the required ‘layer and collation’ format. The lids of the cartons are then glued closed using Bradman Lake’s unique ‘flexible carton control’ technology and presented to a collation unit that will form the final product collation to be sealed in a shrink wrap material.

The roll wrapping system includes:

Primary Packaging: Wrapping.

Secondary Packaging: Race track collating, carton erection, robotic pick and place loading and carton closing.

Tertiary Packaging: Collation and shrink wrapping.

Other configurations are available based on the customers’ requirements.

Bradman Lake packing systems utilise proven technology. The collations are fully supported through the twin cascade loaders. To minimise product damage and maintain collation form, Race Track technology collates the required pack count to end-load into the carton. The wraparound case packer allows for material savings via flat blanks and skeletal case formats.

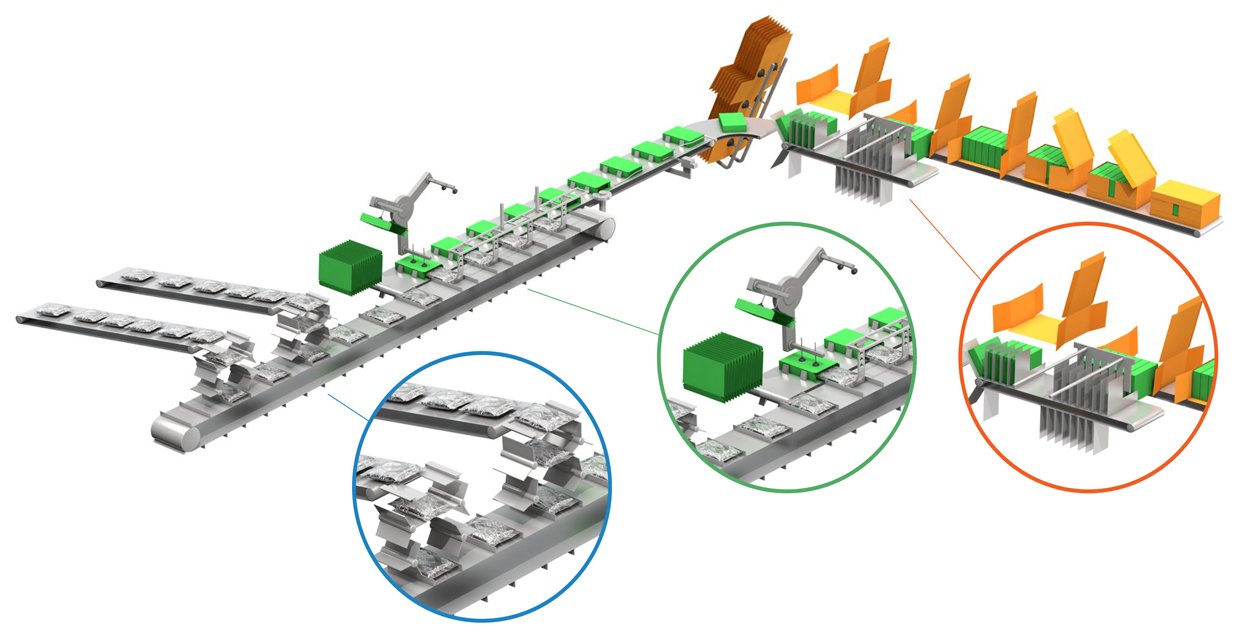

The sachet wrapping system includes:

Secondary Packaging: Twin cascade loader and race track collating.

Tertiary Packaging: Race track carton orientation and collation and case packing.

Other configurations are available based on the customers’ requirements.

The robot places products on trays, and the shrink wrapper employs an ‘over wrap’ principle, using a film application method that takes film from a single reel, trims it, and wraps it around the product with an overlap beneath the pack, sealing it as it passes through a heat tunnel. Besides the increased speeds possible, the lack of a traditional sealing jaw reduces maintenance, facilitated by precise film cutting for registered printed film use.

Tertiary Packaging: Tray loading and shrink wrapping.

Other configurations are available based on the customers’ requirements.

Packaging equipment designed for the pharmaceutical industry

Bradman Lake packaging equipment can be enabled for serialisation and aggregation integration. Labelling, product detection, rejection and integrated case elevators can all be included.

Bradman Lake offers options for various levels of CFR21 Part 11 compliance.

Get in touch

Contact us today for a free consultation, quote, and to request our brochure specifically designed for the pharma and healthcare industries.