Pick and Place Robotics

In addition to the Vision Guided Robotic systems, Bradman Lake produces two variants of the Robotic Top Loader machines, the Dual Race Track (DRT) Top Loader and the Single Race Track (SRT) Top Loader.

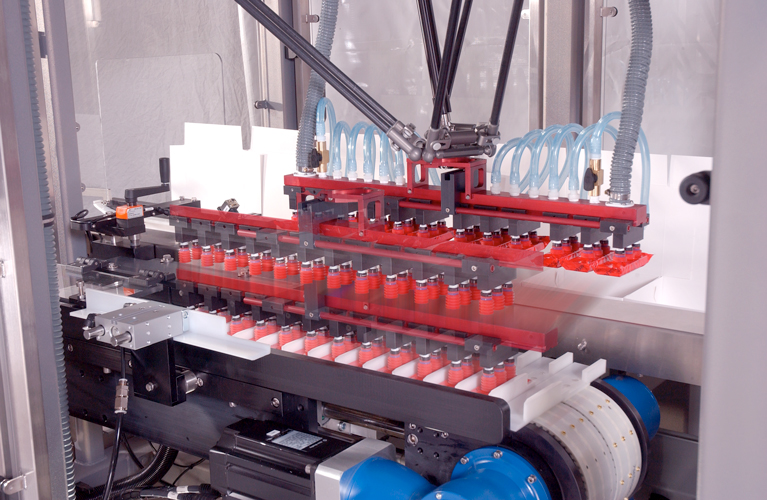

Both machines employ the ABB FlexPicker IRB 360 delta robot for the picking and placement of products, in combination with a precision End of Arm Tool (EOAT).

The machines incorporate intelligent belt technology that provides a unique carton management system of servo-driven belts that accurately spaces pre-erected cartons and delivers them to the carton loading stations. A servo-driven vacuum infeed belt conveys product into the Robotic Top Loader. Misaligned and out of position products are automatically rejected, ensuring high operating efficiencies.

The machines can produce either ‘flat-pack’ or ‘on edge’ collations.

Models

The DRT Robotic Top Loader is a multifunctional machine capable of top-loading products into multiples of cartons, trays, and cases or collating, position synchronising, and transferring product into a moving infeed of an end-load cartoner or multipack flow wrapper.

Dual Loading Robotic Top Loader: For ultimate secondary packaging flexibility, this DRT top loader provides dual loading functionality. Loading either side of the race track typically with a carton management system on one side and a multipack flow wrapper infeed on the other.

Dual Infeed Robotic Top Loader: This version of the DRT Robotic Top Loader is equipped with dual infeeds feeding overlapping DRT’s with a common robot designed to accept products from two primary sources.

The SRT Top Loader comprises one pair of servo-driven transmission belts with one continuous set of product-specific pockets attached. The footprint of this machine is very compact.

Bradman Lake is an innovator of flexible automation using parallel axis robotics technology. The increasing demand to pick and place randomly orientated products, without sacrificing performance, has given the Bradman Lake Group significant opportunity in the core industry sectors in which it operates.

Future Proof Design: The Bradman Lake’s Vision Guided Robotic (VGR) range of equipment has a modular design that allows for handling a wide range of products, collations, and formats. Individual or multiple products are progressively picked and loaded into the continuously moving infeed of the end load cartoning equipment or top load cartons, in the required quantity, to create the collation required.

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request