Roll Wrapping

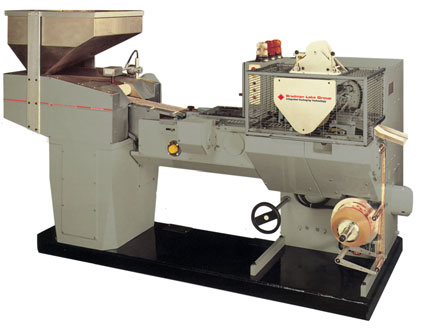

Roll wrapping is an effective way of packaging small round, square, and rectangular products. Bradman Lake has taken this principle and developed a more effective, efficient, and accessible machine.

Our range of roll and stick wrapping machinery allows for precise adaptation to the client’s individual requirements. From a single machine to a multi-machine system, Bradman Lake Roll and Stick Wrappers guarantee quality and reliability.

A wide range of optional features are available to enable the machines to be readily adapted to meet the customer’s specific requirements.

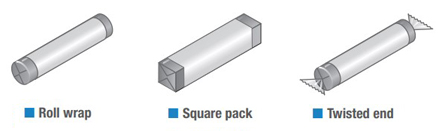

Packaging Styles

Models

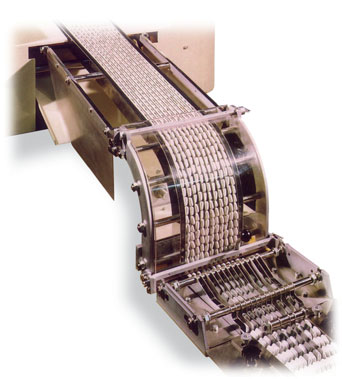

The S2000 series is a well established range of roll and stick wrapping machines which are equally at home as stand alone machines or being incorporated into complete automated packaging lines.

A variety of feeding systems, including colour or flavour sequence feeding, are available for most models in the range. Designed to handle round compressed tablets, dragees, chocolate pieces, boiled sweets, pre-wrapped chews and candies, gums and pastilles, the S2000, and its larger pack size range version S2000L, produces packs in a roll form and with a choice of folded or twisted ends styles.

Standard Features

- Vibratory pre-feed hopper.

- Vibratory sifter plate to remove dust and debris.

- Agitating vanes feeder and product level control.

- Stainless steel infeed chain bars.

- Short pack detection.

- No product no pack function.

- Inner foil and outer label feed.

- Double wrap with point folded ends.

- Rotating wheel and mechanical dabber hot glue application.

- Synchronous motor for print registration correction.

- Rolling head and folders.

- Short belt discharge unit, with independent motor drive.

- Debris trays beneath infeed chain and pre-feed hopper.

- Mechanical overload clutch on main drive mechanism.

- One shot lubrication system.

- Single set of size parts, modular for ease of removal.

- AC main motor drive with inverter speed control

Integral electrical cabinets. - Full interlocked guarding

Robust construction.

The S2000 series is a well established range of roll and stick wrapping machines which are equally at home as stand alone machines or being incorporated into complete automated packaging lines. A variety of feeding systems, including colour or flavour sequence feeding, are available for most models in the range. Designed to handle

square or rectangular compressed tablets, dragees, chocolate pieces, boiled sweets, pre-wrapped chews and candies, the S2000S, and its larger pack size range version S2000SL, produces packs in a stick form and with folded ends.

Standard Features

- Vibratory pre-feed hopper.

- Vibratory sifter plate to remove dust and debris.

- Agitating vanes feeder and product level control.

- Anodised infeed chain bars.

- Short pack detection.

- No product no pack function.

- Single reel feed.

- Single or twin wrap with point folded ends.

- Rotating wheel and mechanical dabber hot glue application.

- Synchronous motor for print registration correction.

- Four head pocket wheel.

- Heat seal discharge unit, pack push pack.

- Debris trays beneath infeed chain and prefeed hopper.

- Mechanical overload clutch on main drive mechanism.

- One shot lubrication system.

- Single set of size parts, modular for ease of removal.

- AC main motor drive with inverter speed control.

- Integral electrical cabinets.

- Full interlocked guarding.

- Robust construction.

The S series is a well established range of roll and stick wrapping machines. The S3000 is a specialist high speed roll wrapping machine, designed to wrap small diameter confectionery products using a single reel of unprinted or randomly printed wrapping material. The machine is dedicated to producing packs with twisted ends.

Standard Features

- Left hand operation.

- Vibratory pre-feed hopper.

- Vibratory sifter plate to remove dust and debris.

- Agitating vanes feeder and product level control.

- Anodised infeed chain bars.

- Short pack detection.

- No product no pack function.

- Inline single reel feed with low level wrapping material reel shaft for easy loading.

- Single overall wrap with fan tail twisted ends.

- Simple adjustable discharge chute.

- Debris trays beneath infeed chain and pre-feed hopper.

- Mechanical overload clutch on main drive mechanism.

- Oil bath lubrication.

- Single set of size parts, modular for ease of removal.

- Separate indexing units for infeed and rolling head.

- AC main motor drive with inverter speed control.

- PLC control.

- Integral electrical cabinets.

- Full interlocked guarding.

- Machine mounted on single base plate.

- Robust construction.

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request